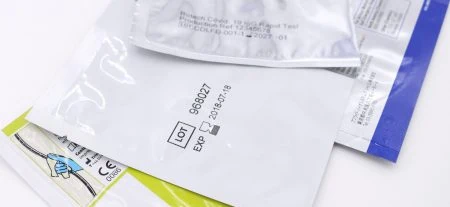

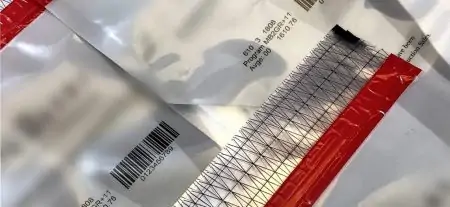

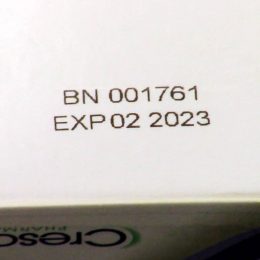

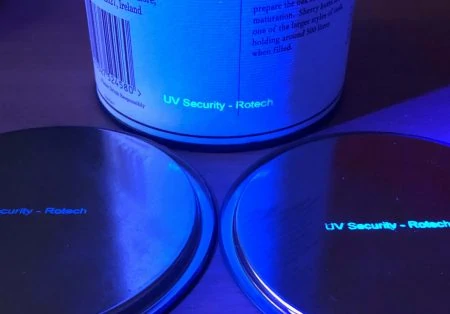

To protect against counterfeiting and improve patient safety, codes and product information on medical packaging need to be high-quality and durable.

Medical

Medical packaging coding and labelling solutions

On-line industrial printers for medical products

Clean and odour-free, our high-resolution thermal inkjet (TIJ) printers are ideal for printing production dates, expiry dates and batch codes directly onto medical packaging such as cartons and Tyvek®

Where there is a need to apply a large amount of information onto a pack, a thermal transfer (TTO) printer can be provided. Alternatively, our Integra PP Razr 34 can print high-resolution prints up to 34mm, on both porous and non-porous surfaces.

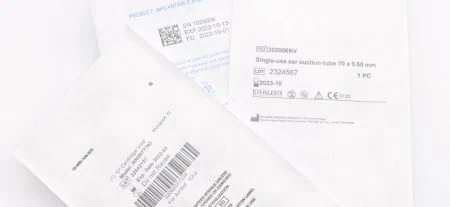

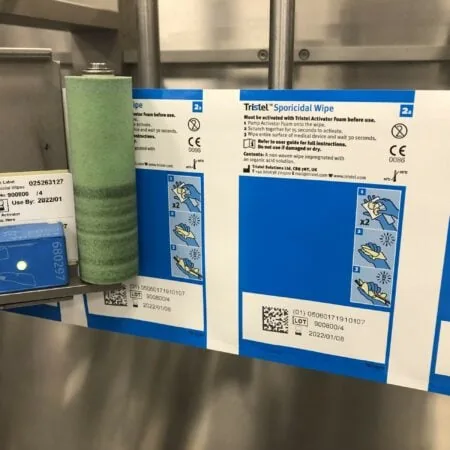

Labelling medical packaging

If a label is required on the pack, a print & apply labelling system can be easily integrated into your production line or onto your off-line feeding system if required.

Feeding systems - off-line coding

Feeding systems are ideal for printing or labelling flat-form packaging away from the production line (off-line).

We have a comprehensive range of feeding and handling systems for almost any type of medical packaging. The product and information being printed will determine which system is right for you.

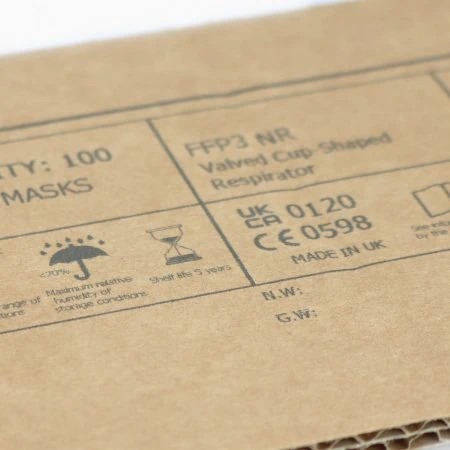

Printing secondary packaging

For outer cases, our high-resolution large character marking (LCM) printers offer a low-maintenance, high-speed alternative to labelling. The innovative systems are capable of printing verifiable barcodes, text, and graphics on areas up to 500mm wide.

Applications

Resources

Success stories

Related Products

Talk with an expert

Still unsure what you need? Our coding experts are on hand to help you find a solution that matches your exact requirements.