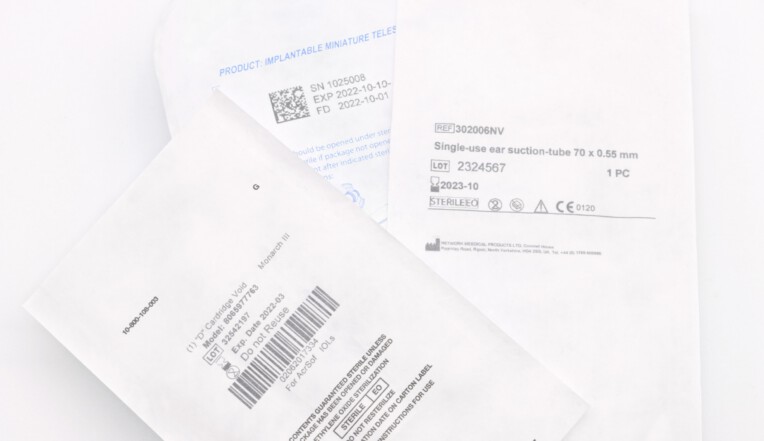

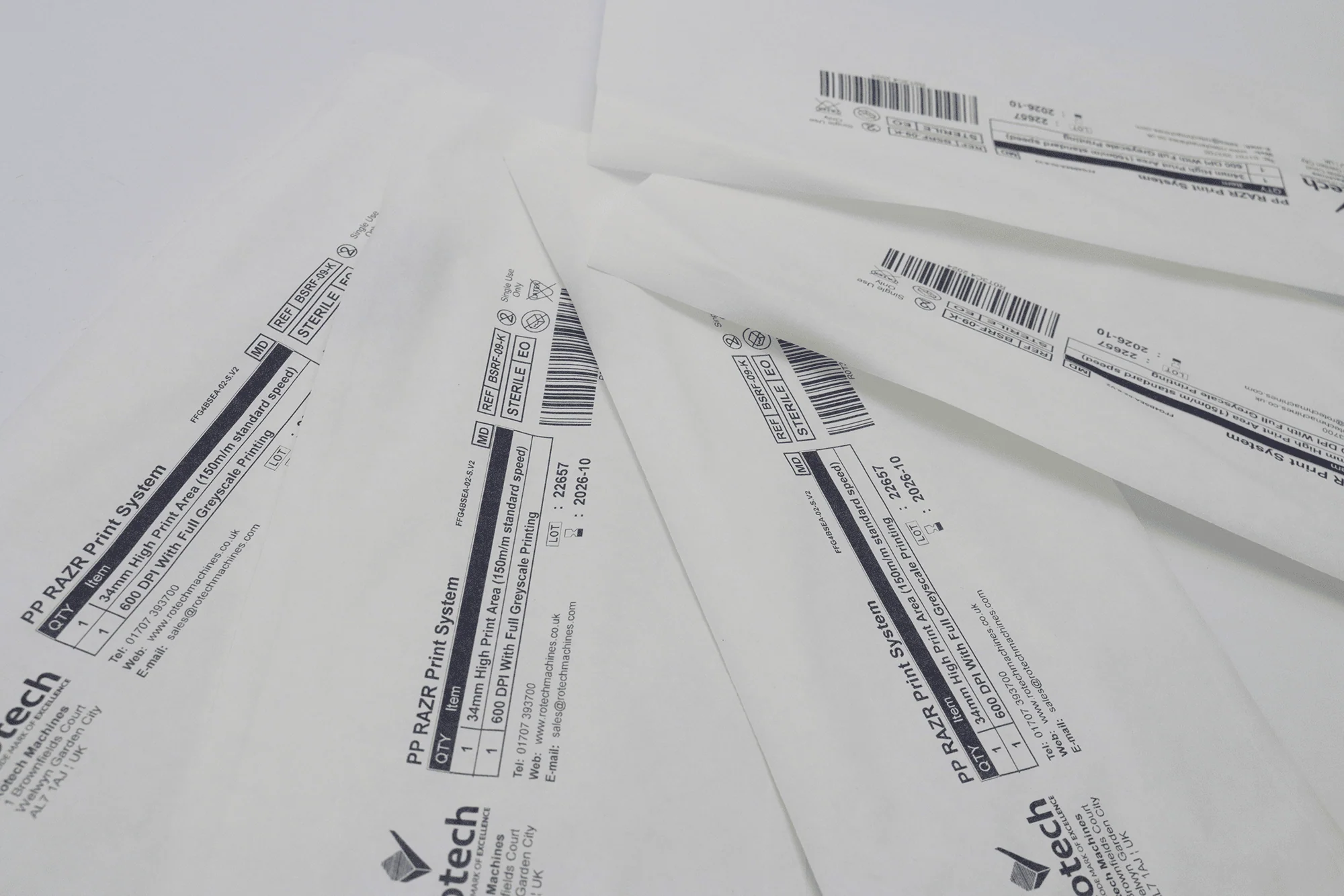

Excellent quality printing on Tyvek pouches and lidding material

Tyvek® is a popular choice for packaging medical devices as it is lightweight and breathable, yet durable and water-resistant.

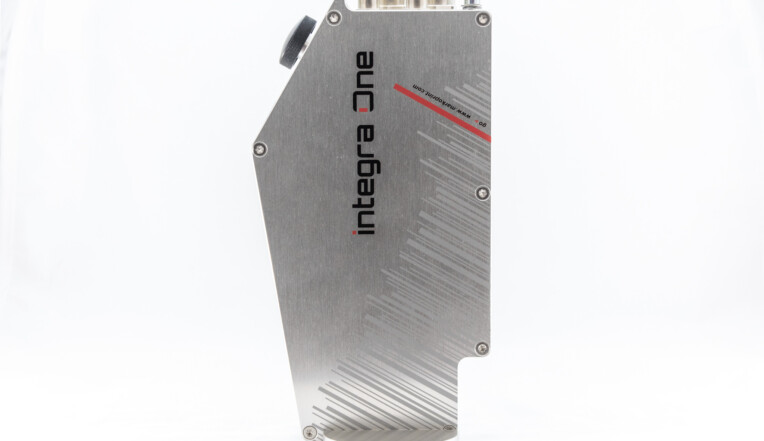

Achieving high-quality print on Tyvek® that complies with UDI track and trace initiatives is possible with a range of overprinting technologies and can improve efficiency and reduce cost by removing the need for a pre-printed label.