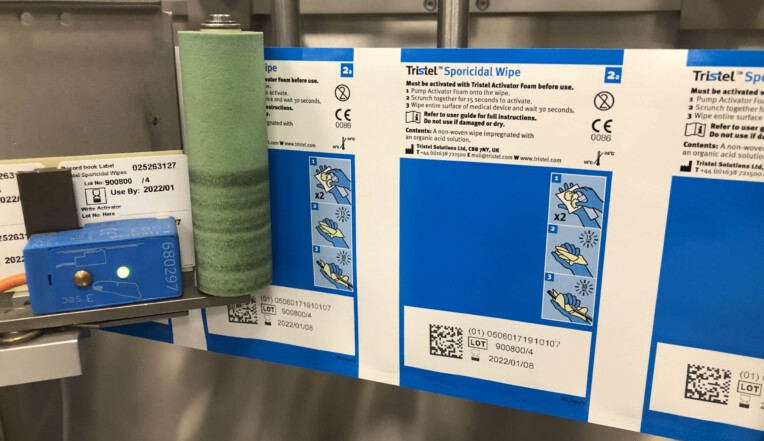

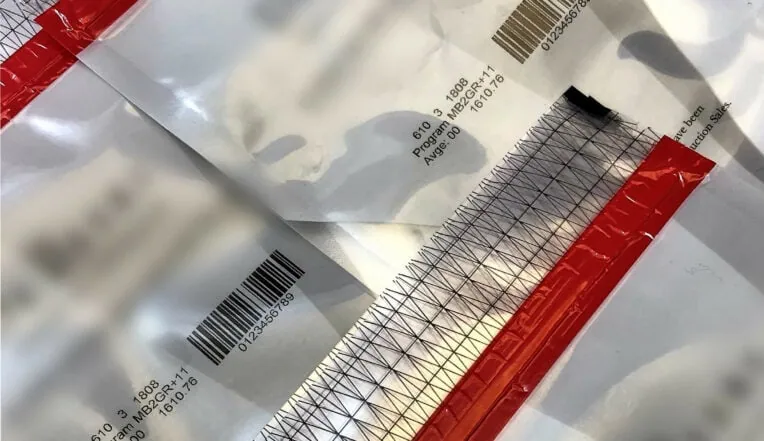

Print excellent quality codes and marks onto stick packs and sachets

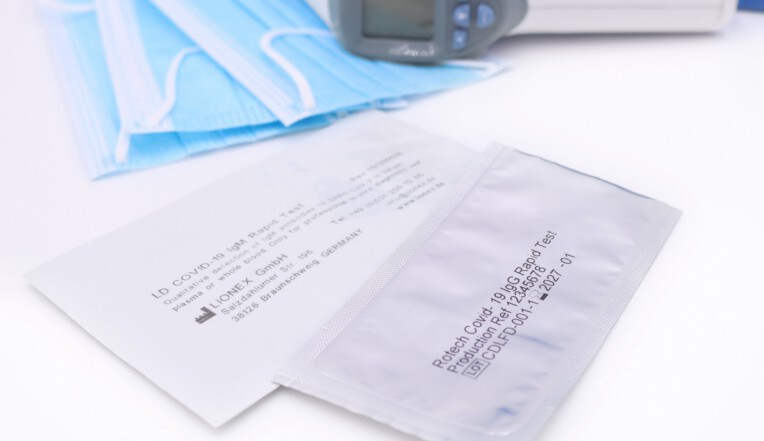

Stick packs and sachets are commonly associated with pharmaceutical, food and cosmetic products that require a printed batch number or best before date. For food manufacturers they provide convenience and portion control, mostly associated with the hospitality sector.

For pharmaceutical companies, they present a tightly sealed, single use product with a controlled dosage. Both instances demand accurate, visible coding and marking to guarantee consumer safety and peace of mind.