Ideal solutions for coding and labelling outer cases and boxes

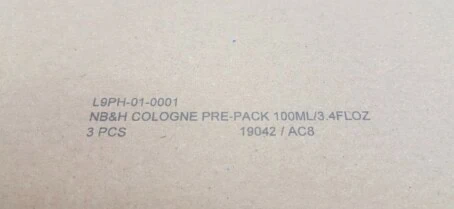

Billions of cardboard boxes are shipped worldwide every year. To avoid any delays and minimise the risk of human error, it is essential that shipping and traceability information is shown in a clear, readable format.

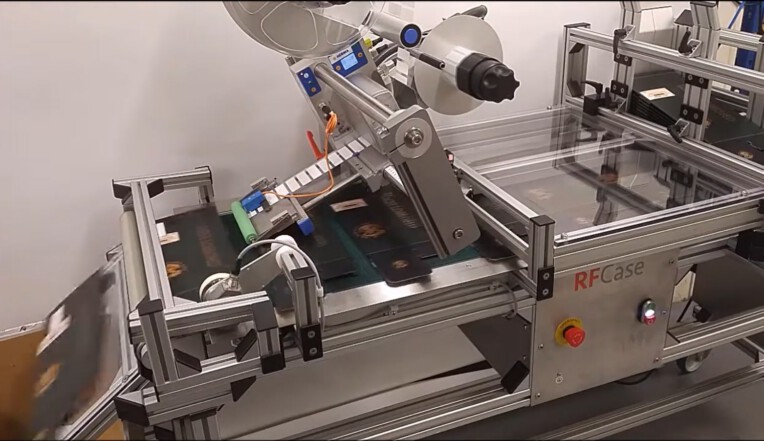

The two main methods for reliable, high-quality outer case coding are applying labels and printing directly onto the box using case coders.