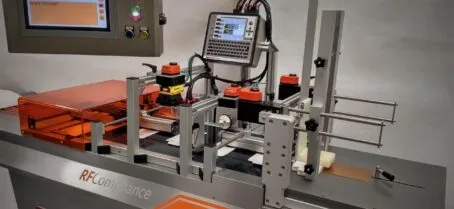

British-made systems for coding or labelling flat form packaging with ease.

Our RF range of feeding systems allow flat-form packaging to be coded and/or labelled in a quick and reliable way. You simply stack the product in the hopper and watch as it is automatically fed under the printer, labeller (or both) before being returned to a stack, ready for operator removal.

All of our feeders are designed and built here in our UK factory, to exacting standards. They can be fitted with most coding and marking technologies to suit your individual application needs.