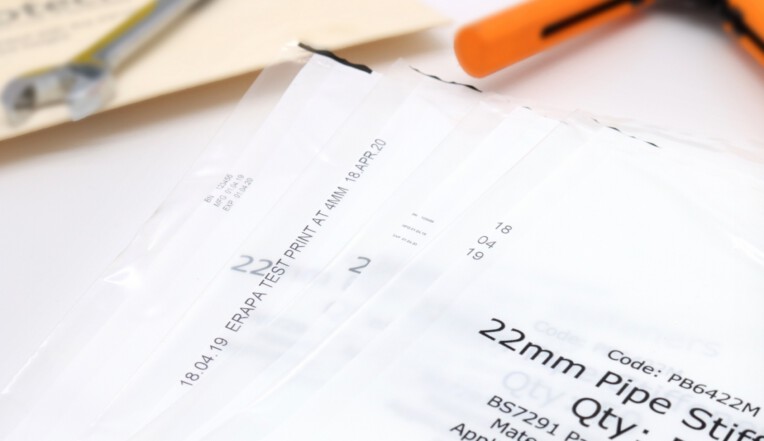

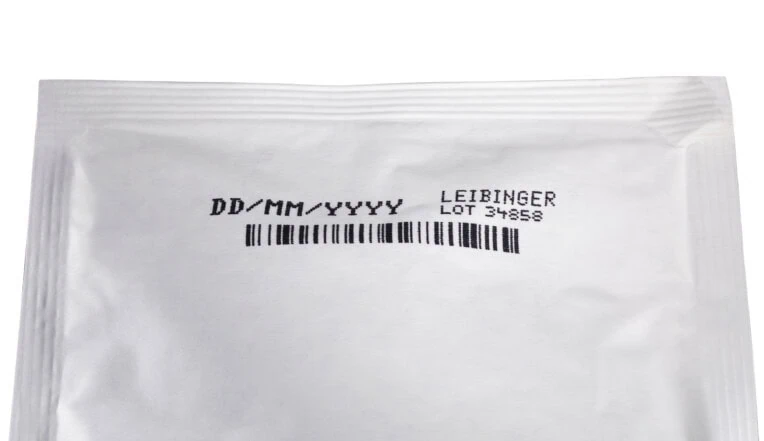

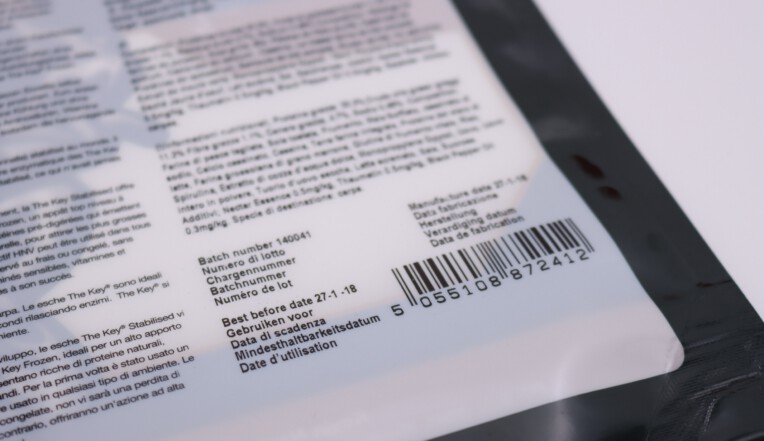

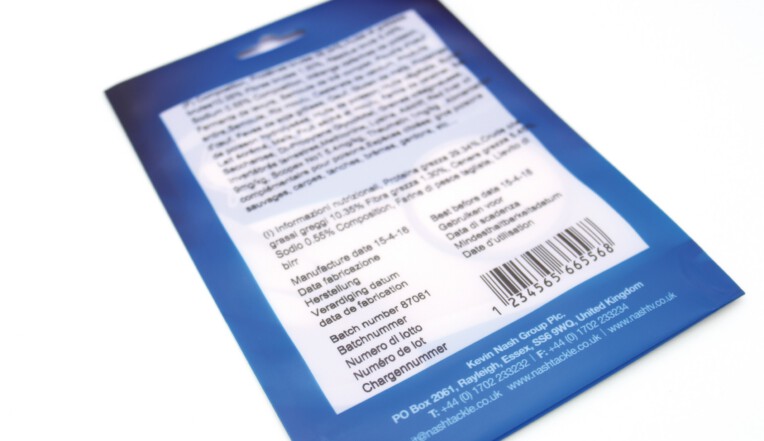

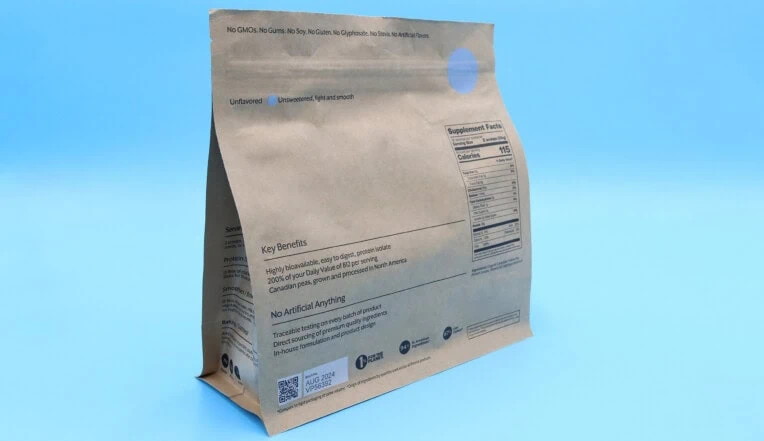

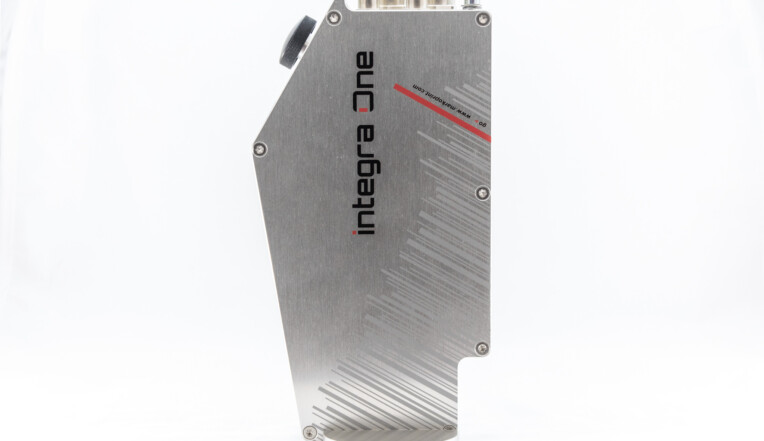

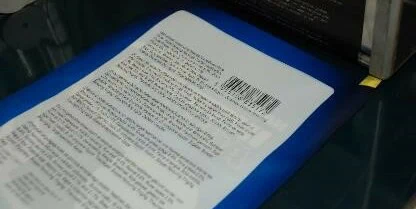

Reliable coding & marking for bags and pouches

From batch numbers to expiry dates, our innovative solutions deliver crisp, high-quality variable information on pre-formed bags and pouches, every time. Whether you’re working with paper, plastic, foil or laminated films, we offer the ideal technology to integrate seamlessly into your line and keep your production running smoothly.