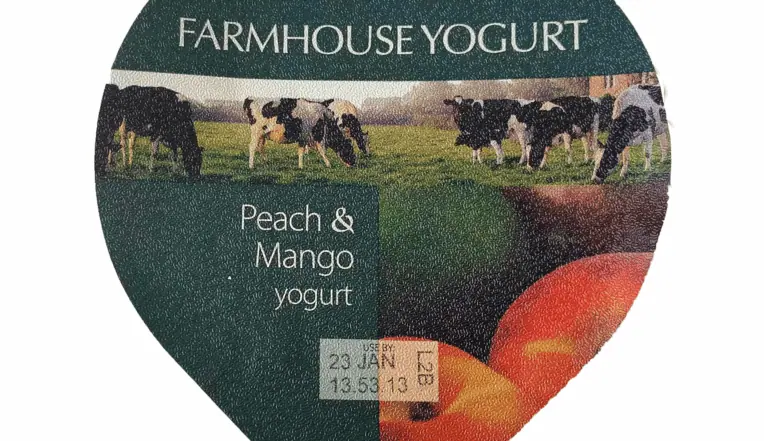

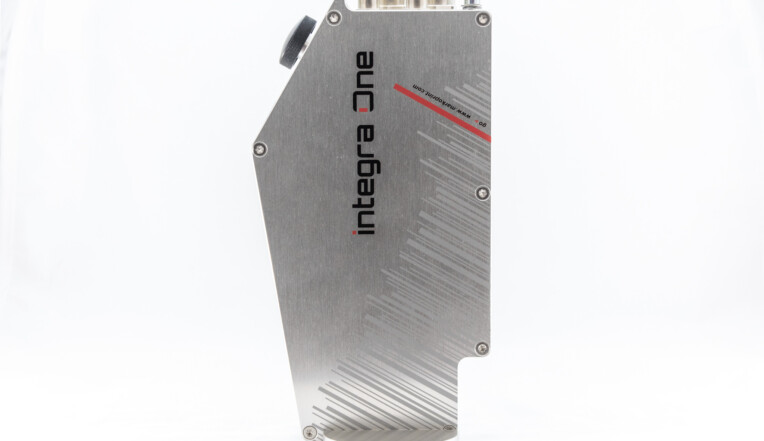

Solutions for coding aluminium foil lids – print variable data onto yoghurt pots and dairy products with ease

Aluminium foil lid coding is a common application for the dairy industry who apply code directly to yoghurt, cream and custard pots.

The use-by-dates, batch numbers or variable information applied must be high-resolution and durable to guarantee consumer safety and product traceability.