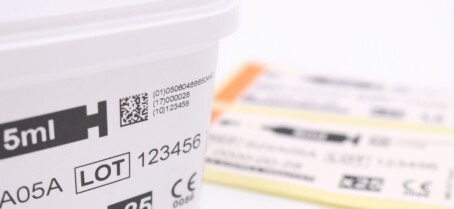

Industrial inkjet printing technology allows companies to print critical information, such as batch codes, serial numbers, barcodes and

traceability information onto their products or packaging. We have several inkjet technologies available, each with their unique strengths,

allowing us to satisfy most applications.

Industrial inkjet printers for your production line

Our technologies, an overview

Thermal inkjet (TIJ) printing – in partnership with Markoprint

Clean, cartridge-based technology with a high print resolution. The compact units are simple to operate and are completely maintenance-free. Printing on both porous and non-porous materials made possible with a range of solvent and water-based inks available.

Key benefits:

- Achieve excellent quality prints, of up to 600dpi

- Easy to integrate with existing equipment

- Instant start up and shut down – ready to print when you are!

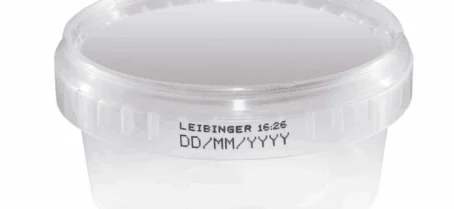

NEW: Continuous inkjet (CIJ) printing – in partnership with LEIBINGER

CIJ units are ideal for tough production environments and can print onto virtually any surface at very high speeds. Made with unrivalled levels of vertical integration and equipped with automatic nozzle sealing technology, LEIBINGER printers are undoubtedly the best in class.

Key benefits:

- Impressive 413m/min top running speed

- Can print on any substrate – including uneven or curved surfaces

- Unique nozzle seal technology means quick start up and shut down, especially when compared with competing brands

Rotech partners with industry leader LEIBINGER

Rotech has joined forces with LEIBINGER to bring world-class CIJ technology to our customers.

This partnership brings together decades of expertise, German precision and British ingenuity, setting new standards for performance & reliability. It’s CIJ reimagined.

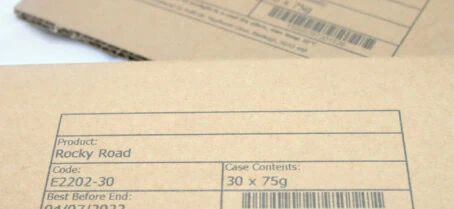

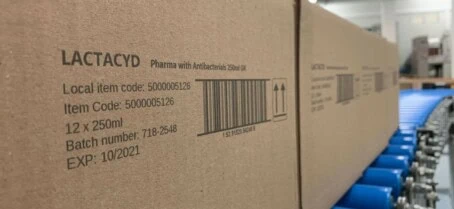

Large character marking (LCM) - in partnership with Markoprint & Kortho

Ideal for direct case coding. LCM printers allow for large amounts of information previous printed on a label, to be printed directly onto the box. By moving away from labelling, you save costs on consumables, printing, and the need for an application system.

Key benefits:

- Prints high-resolution, scannable barcodes, allowing for full supply chain traceability.

- Reduces waste and aids box recyclability

- Huge cost reduction when compared to labelling

Got a project to discuss?

Our coding experts are on hand help you find a solution to match your exact requirements.