Happy that the introduction of the RF Lite had made a positive impact to their production process, Orange County looked to Rotech for a way to automatically overprint variable data directly to the labels being applied to the vials of oil.

The compact nature of Rotech’s Integra TIJ printer means that it can be easily integrated into existing production lines, to work seamlessly with other equipment, including label applicators.

The addition of the TIJ printer to Orange County’s labeller meant that they no longer had to pre-print labels or apply fiddly secondary labels by hand, meaning they saved a lot of time and no longer faced overstock/waste.

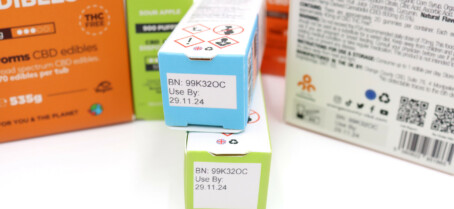

The printer also comes with its own iDesign formatting software. The company can create and edit batch and date codes, control output speeds, view job status and check ink levels. The software allows them to set the printer to print their Batch and Expiry information onto the exact area on the wraparound label.

Orange County is definitely feeling the effects of automating and streamlining their coding processes with clever coding. They’ve been able to drastically reduce labour costs, improve production throughput, and reduce costs involved with pre-printed stock.

Our team has been highly praised since the installation. Head of R&D and Production at Orange County said, “we couldn’t be happier about our experience working with Rotech! When we needed a coding machine for our business, they came highly recommended, and they didn’t disappoint. The team at Rotech was incredibly knowledgeable, professional, and attentive to our specific needs. They helped us select the perfect coder that streamlined our production process and improved our efficiency. Their exceptional customer service and after-sales support have made us feel valued and confident in our investment – we couldn’t be happier with the results. I highly recommend Rotech to anyone in need of top-quality coding solutions!”