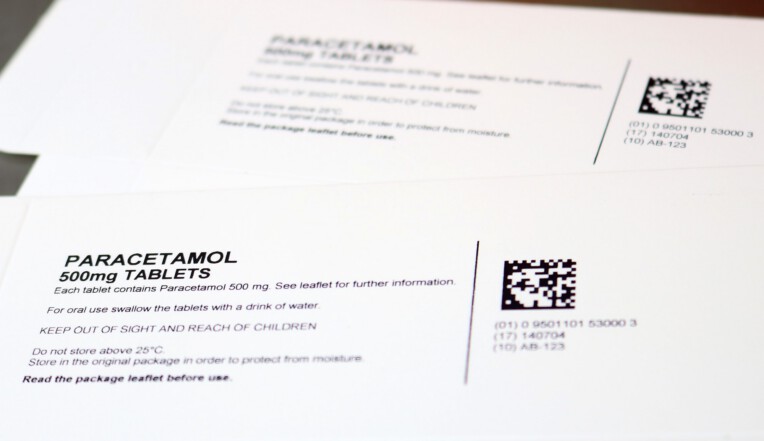

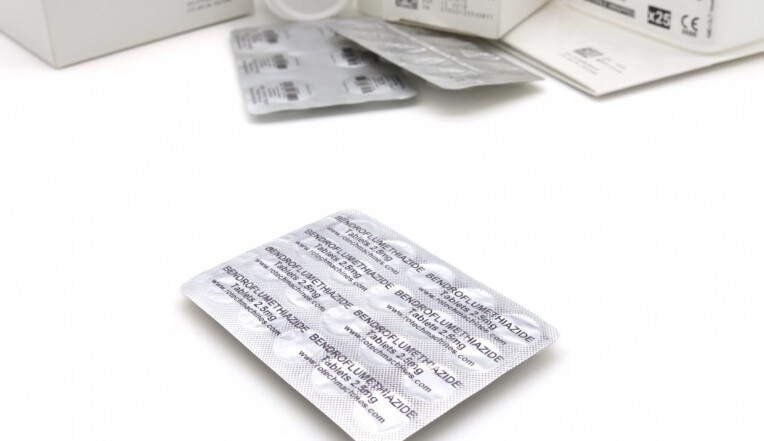

Accurate coding is essential in the pharmaceutical industry, where traceability, patient safety and regulatory standards are non-negotiable. Every product must carry legible batch codes, expiry dates and often serialised data to support anti-counterfeiting measures and global track-and-trace regulations. Our coding solutions are designed to deliver precision and full compliance across a wide range of pharmaceutical packaging formats.

Pharmaceuticals

Pharmaceutical coding solutions

Got a project to discuss?

Our coding experts are on hand help you find a solution to match your exact requirements.