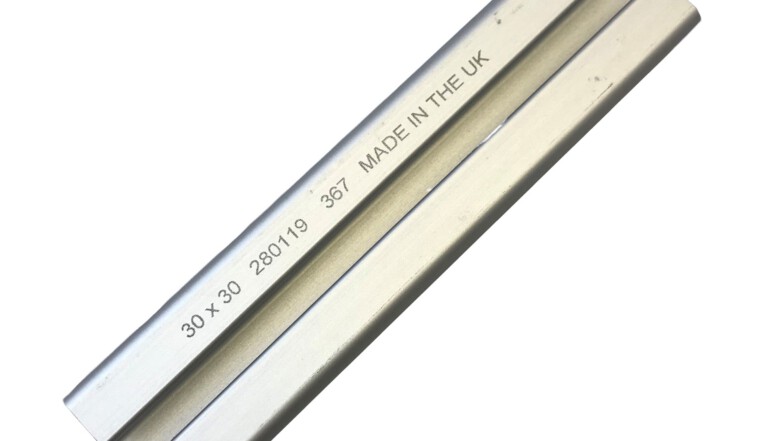

Print excellent quality codes and marks onto plastic pipes and extrusions

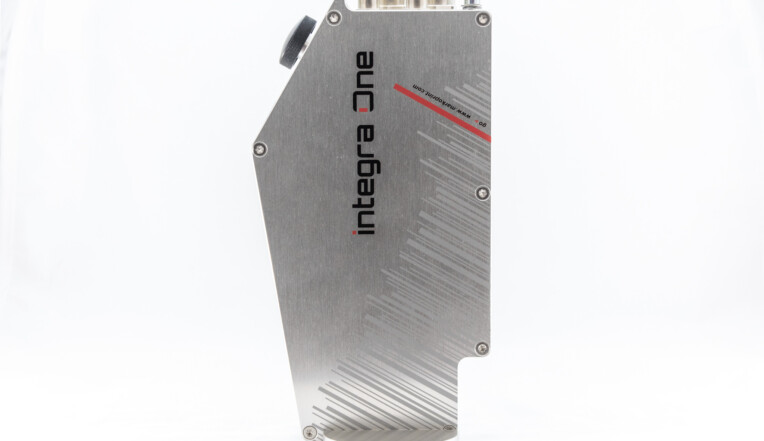

Coding and marking is crucial to achieve security and traceability on plastic pipes and extrusions. Choosing a solution that can manage variation and withstand the changing manufacturing environments is key.