Most packaging requires a date code presented in the form of a standard day/month/year, however this varies depending on what information needs to be pulled from the code.

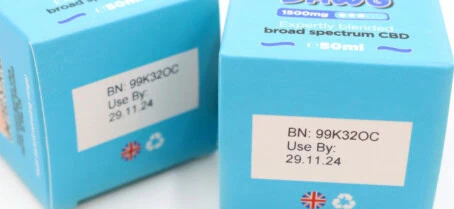

Best before dates, use by dates and display until

Widely recognised date codes, which highlight the day, month or year a product should stop being displayed or consumed.

Best before, use by and display until, have different meanings and should be read as such. Either as a rough indicator of a products freshness, or a strict safety measure.

Julian dates

(Funnily enough) Julian dates were created by the one and only Julius Caesar.

They are seven-digit numerical codes that provide information on when a product was packaged.

The first 3 digits highlight the consecutive day of the year. So, for example, January 1 is 001 and December 31 is 365.

We mainly encounter these dates on plant tags and horticultural packaging, and on certain food items like eggs.

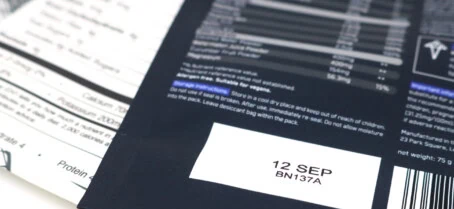

Batch and lot numbers

Information can be extracted from a batch or lot number, including the date that a specific product was manufactured.

These codes are most useful when it comes to stock rotation, product recalls and supply chain management.

Serial date codes

It’s getting serious now. This is where the top guns get involved, the pharmaceutical and medical industry.

Serial codes are vital within these sectors to individually identify products. This is done incrementally or sequentially and meaning every piece of packaging has a unique code.

They will usually be double, triple, quadruple checked by a camera system to guarantee consumer safety and peak traceability.

2D barcodes and data embedded barcodes

The potential for scannable barcodes and QR codes is huge when it comes to batch and date coding. Not only can they provide information on a products quality to consumers, they can also be used by suppliers and manufacturers for efficient stock rotation and pricing indicators.

The barcodes provide an all-in-one approach rather than individually printing each piece of variable information.