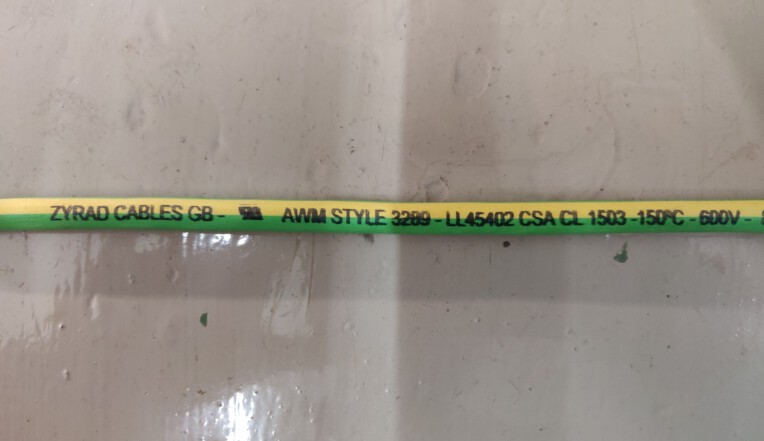

High-performance solutions for cable and wire coding & marking

Long-lasting codes are crucial for traceability and security on cables and wires. The chosen coding and marking solution must be capable of running at high speeds to keep up with production. Printing can be done directly onto the wire, on small labels or tags, and even applying code to the cable reel cores. Manufacturers may want to display the voltage, type of wire, sizing, or batch number.