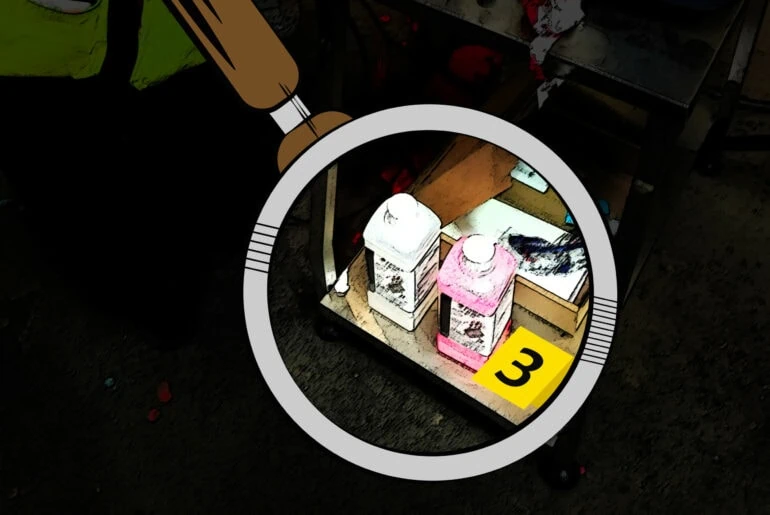

CLUE 3 – Costly ink refills and hazardous MEK fluids

The final and most crucial piece of evidence from our coding crime scene. Large bottles filled with volatile fluids that are hazardous to human health.

These look suspiciously like the MEK fluids and ink bottles used with CIJ printers. The warning symbols should be enough to avoid these dangerous liquids. However, they must be regularly topped up by operators, causing excess costs, downtime, and damage to the environment.

TIJ on the other hand, requires only one consumable, does not use MEK fluids and its inks use minimal solvents. This leads to a much safer environment for operators.

This particular coding crime is bigger than we thought, costing the manufacturer thousands in consumables and downtime. Leading us to discover the culprit…. a CIJ coder, the cause of many coding and marking crime scenes across the nation!