One of the top concerns raised by manufacturers seeking guidance on their coding and marking operations, is that the maintenance involved in keeping their coding system running smoothly is too costly. They usually all have one thing in common – that they are coding their products using continuous inkjet (CIJ) technology.

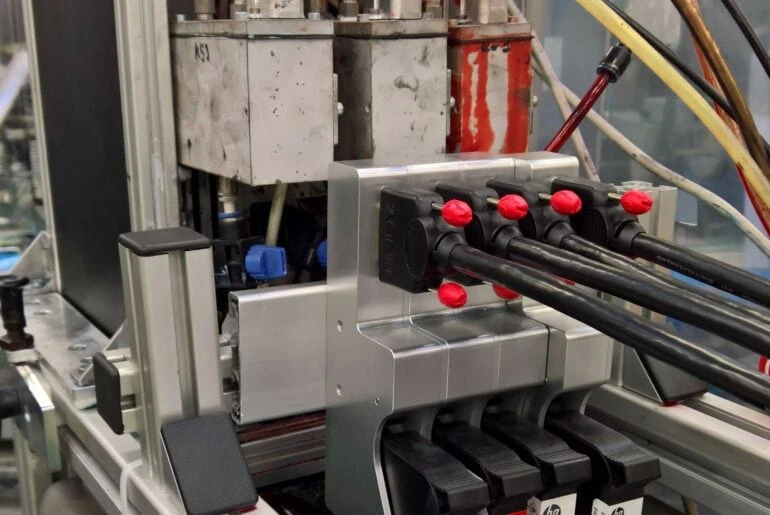

Replacing an outdated CIJ system with a modern thermal inkjet (TIJ) coder has been a game-changer for many manufacturers. CIJ legacy printers are made up of many wearable parts and components, from ink pumps and filters to sensitive printheads, all needing regular maintenance to ensure smooth operation. This necessary maintenance is often labour intensive and time-consuming, and as such presents a huge financial implication to manufacturers, who risk downtime if neglected.