Continuous Inkjet (CIJ), the fast-drying, non-contact printing technology has been the preferred method to code and mark packaging for many years. It’s ability to print on to virtually any surface at high-speed meant that it was unrivalled for many applications. Until now that is.

Over the past decade, Industrial thermal inkjet (TIJ) printers have come on leaps and bounds. The two main barriers that prevented manufacturers from adopting the technology; cost and ink performance have been broken down. TIJ units are now comparable in cost with CIJ units and game-changing ink advancements mean that TIJ printers no longer struggle to print onto shiny or non-porous surfaces.

Now, as TIJ is a match for CIJ in terms of its capabilities, it’s time to look at the two technologies in more detail. Why choose one over the other?

Reliability

Reliability is crucial when selecting a printer to code or mark variable information onto your packaging or product. Manufacturers – particularly those in the FMCG sector – need a system that will produce quality codes, quickly and consistently with minimal downtime.

Both technologies can produce legible codes onto virtually any surface at speed with great accuracy. CIJ is the fastest of the two, with line speeds of up to 2,000 ft/min.

However, when quality of the print is paramount, thermal inkjet is the way to go – the technology offers excellent print quality of up to 600dpi, so it can handle the sort of 2D precision codes common in applications such as pharmaceuticals, where CIJ systems can struggle.

Downtime is also less with a TIJ system as there is no start-up or shut down time, enabling effective, intermittent operation. CIJ systems take several minutes to warm up, which means that users often keep them running all day so they don’t risk holding up production.

Ease-of-use

CIJ systems are relatively complex with ink pumps, pressure regulators, filters, and sensitive print heads.

In contrast, TIJ printers are modular systems with a controller and a print head holder connected by a cable. Every time that the ink delivery system is changed, so is the whole ink delivery system.

Cost of ownership

There are suppliers who will virtually give away a CIJ printer, knowing that it will be paid for indirectly in the form of ongoing maintenance and consumable costs. Therefore, a meaningful price comparison can only really be drawn by looking at the cost of ownership. Regardless of the initial equipment cost, TIJ will cost less than CIJ over its lifetime. As a rule of thumb, TIJ will work out at two thirds of the cost of CIJ when measured in terms of cost per 1000 prints.

TIJ systems also come with lower installation costs (around half the cost of CIJ), less to operate and are maintenance-free which means no service contracts.

Cleanliness

CIJ works by jetting a continuous stream of electrostatically charged ink droplets into a gutter that returns it back into the ink supply. Printing deflects the stream momentarily to aim a series of drops onto the substrate to form each character. Only a small fraction of the droplets are used to print while the rest keep recirculating through the system. Throughout this cycle, the ink is suspended in a methyl ethyl ketone (MEK) solvent-based thinner, also known as the make-up, to maintain the correct viscosity. MEK is a volatile organic compound (VOC), which means it readily evaporates to the atmosphere and must be constantly topped up. It’s also responsible for the characteristic fruity smell that hangs around any CIJ installation.

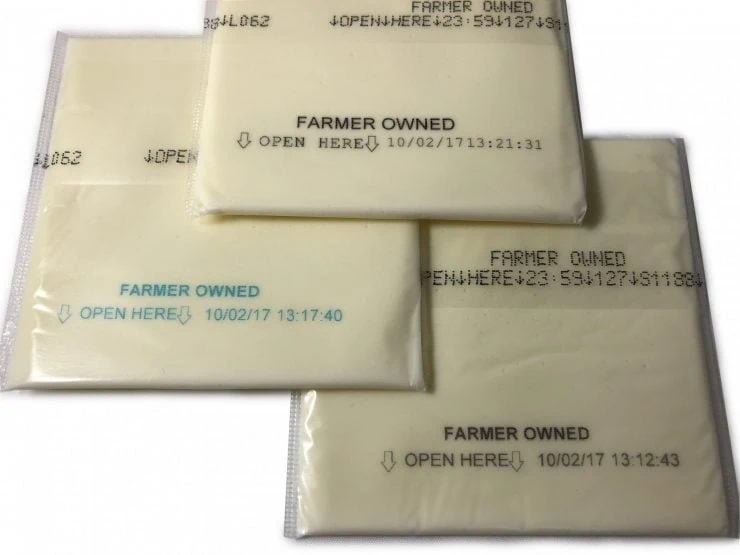

TIJ printers use a simple and robust self-contained cartridge system that combines both a printhead and ink supply system. There is no ink or solvent bottles to contend with, so mess and spillages are non-existent.

Replaceable HP print cartridges mean no more handling of ink bottles. When the ink runs out, throw the cartridge away – no hazardous material shipping or disposal costs.

When choosing coding technology, if you are looking for a system that will be reliable, will improve print quality, is easy to use, has competitive lifetime costs and is clean, why would you not look at thermal inkjet?