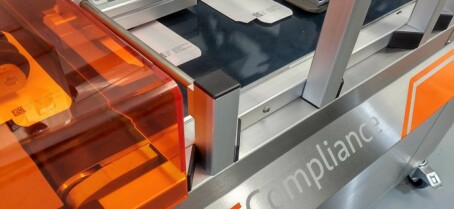

Coding With The RF Auto: More Versatility Delivers More productivity

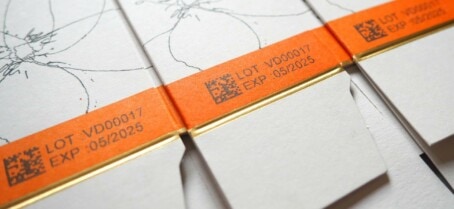

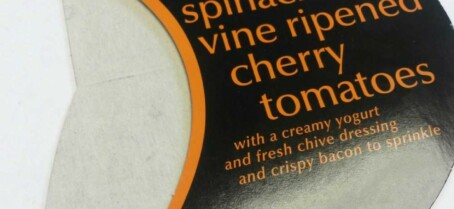

Rotech has developed its new offline RF Auto sleeve and carton friction feeder in response to the coding and handling challenges of the latest ‘lift-the-flap’-style luxury pack sleeves.