The UK manufacturing industry is extremely competitive, especially amidst a cost-of-living crisis. It’s increasingly important for producers to evaluate their processes and ensure that their lines are running as smoothly and efficiently as possible, in order to generate the best possible profit.

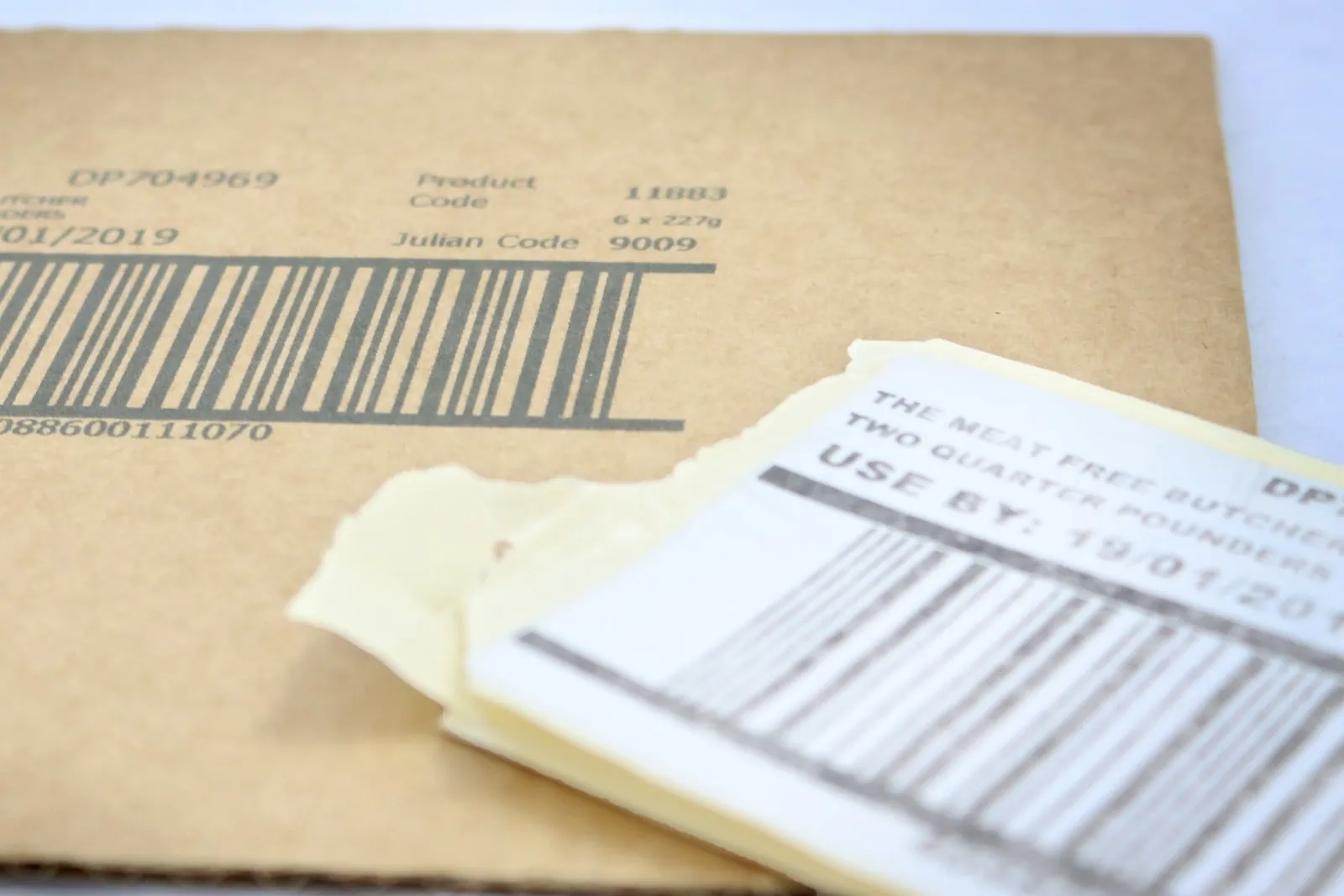

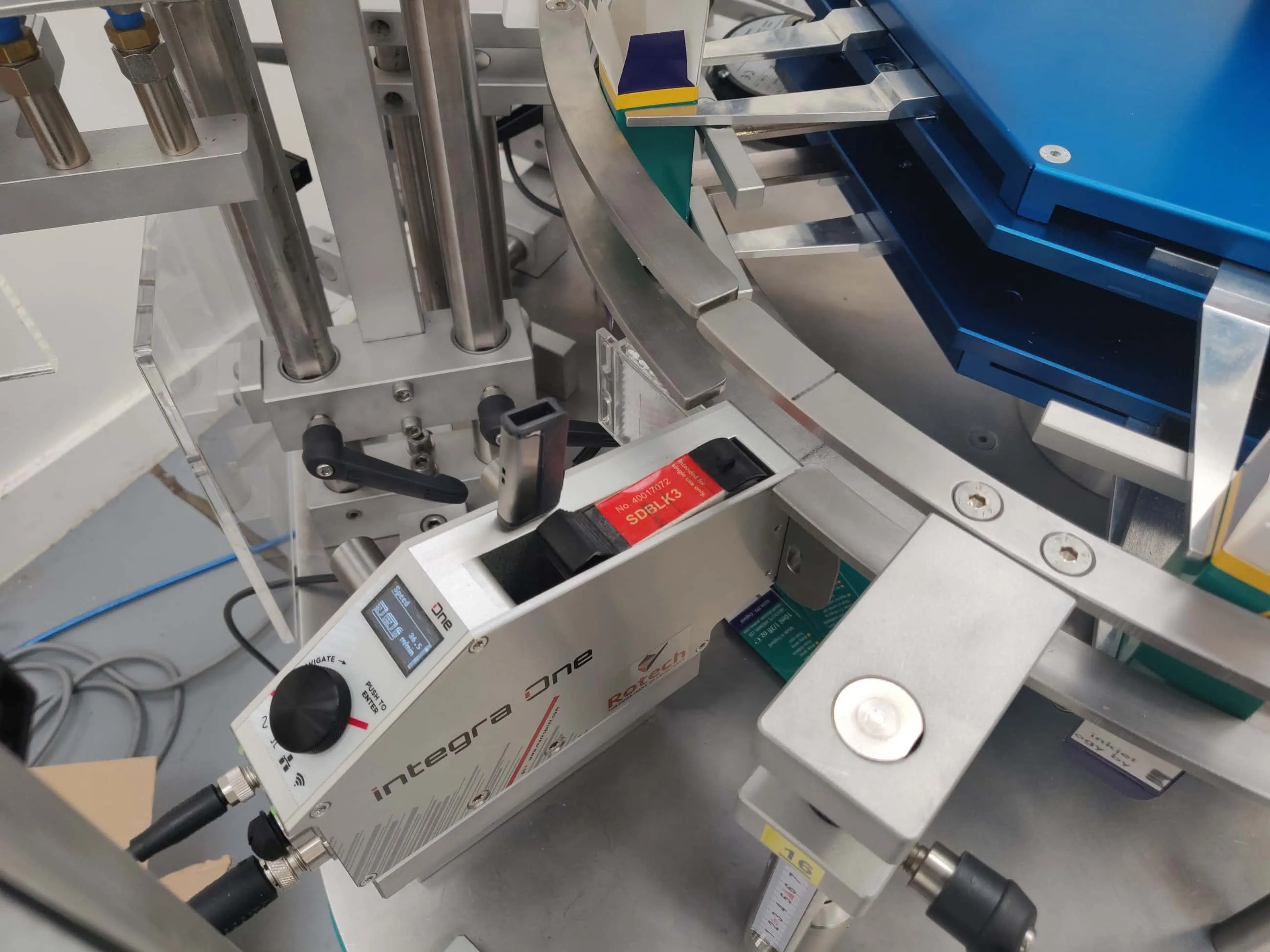

Coding and marking is an essential function for any company producing goods destined for consumers and therefore shouldn’t be overlooked. Just because the process is working, doesn’t mean that it can’t be improved, and made leaner.

By going lean with their coding and marking, many manufacturers have boosted their productivity, welcomed cost-savings and even improved their sustainability credentials – a key factor for many consumers when making a purchase decision.

Here are some things every manufacturer should address to go lean with their coding and marking: