Working to eliminate the cost of human error on the packaging line

Having a continuous supply of boxes that are pre-marked with information about their contents and destination helps minimise the chance of human error as products reach the end of the packaging line. Rotech director Richard Pether explains:

Pre-labelled boxes tell operators what they need to do. If the box is already labelled ‘prawn sandwiches’ they know they should be filling it with prawn sandwiches, not ham. Each box can also be marked up with its destination or whatever code it needs to ensure products end up in the right place.

Rotech’s existing RF range is already well established for offline marking operations in primary packaging, he adds. The new RF Case Feeder was designed to respond to a surge in demand we’ve received from secondary packers looking to adopt a flexible and cost-effective off-line approach.

Offline coding speeds up overall operations by removing the need for a marking step within the packing line itself. This can be an important advantage in high-speed production environments, especially when handling perishable products with short use-by dates, such as chilled foods, for example.

Save time with multi-panel box marking

Marking boxes while flat also offer the added advantage of enabling users to apply codes and labels that will cover two sides of the box once erect. This would be much more complicated and expensive to achieve once the box is assembled. “The cost savings will vary with each application, but the system will always be much simpler,” says Richard.

Many of today’s food manufacturing facilities face an ever-expanding variety of products passing through multiple packing lines. In these situations, pre-marking boxes enable users to install only as many marking systems as they need to meet their capacity requirements, rather than having to install a separate system at the end of each line. For example, one early adopter of the RF Case Feeder uses just two systems to mark up the boxes for 3.5 million packs of sandwiches each week.

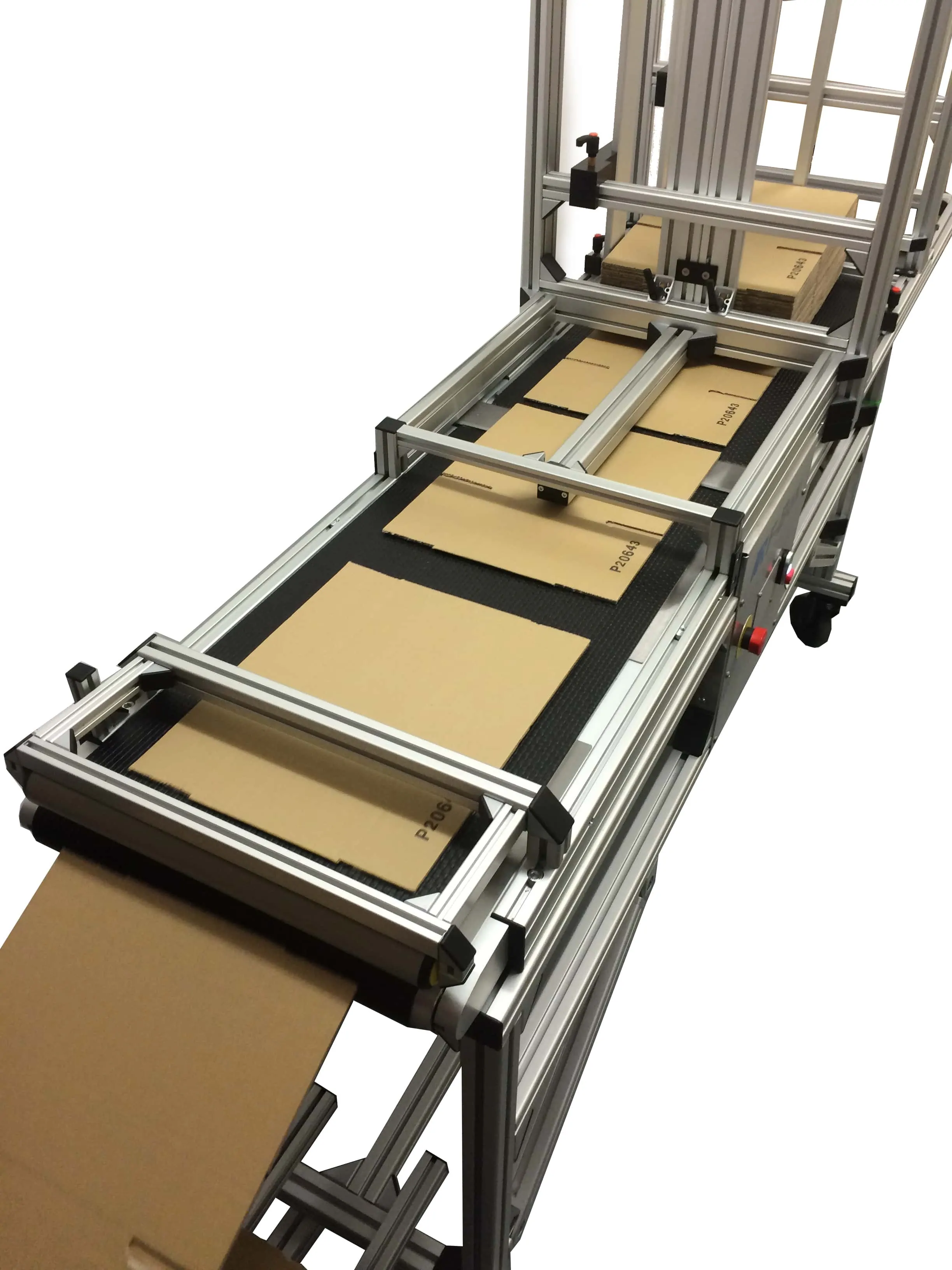

The RF Case Feeder takes flat boxes from the bottom of a horizontal stack and feeds them through the user’s chosen marking system, stacking them again neatly on the other side. Two conveyors working at slightly different belt speeds optimise the gap between each box, so a photocell can trigger the marking system as each item approaches. This enables the RF Case Feeder to achieve the optimum throughput in terms of boxes per minute at the lowest possible belt speed.

Large Area Box Printing

Rotech can customise any feeder to the needs of the customer – one of the many benefits of working direct with the manufacturer. In addition to automatic direct and label printing on to cartons, Rotech can also customise the RF Case Feeder to accommodate large area printing & Thermal Inkjet Technology, allowing customers to apply all box information in any format and at high speed.