Integra PP Razr 34 – Best of Both Worlds?

The launch of the Integra PP Razr 34 printer is something of a revelation in that it runs with the same inks used in a TIJ printer, but offers a seamless, 34mm print height.

From company updates to helpful hints and tips - Rotech's blog is a one stop shop for coding & marking and packaging information.

The launch of the Integra PP Razr 34 printer is something of a revelation in that it runs with the same inks used in a TIJ printer, but offers a seamless, 34mm print height.

Adjusting print settings, monitoring ink levels and editing print jobs is now easier than ever, with the addition of the Integra Vivid

By going lean with their coding and marking, many manufacturers have boosted their productivity, welcomed cost-savings and even improved their sustainability credentials – a key factor for many consumers when making a purchase decision.

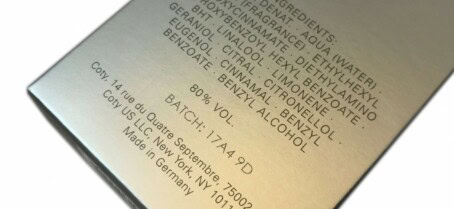

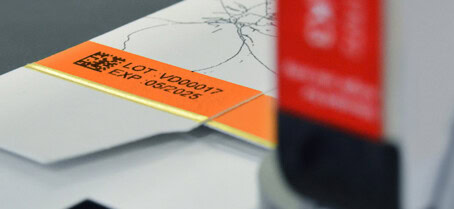

Coding and marking, the process in which variable data such as lot codes, batch numbers and barcodes are applied onto products, packaging or labels is often seen as a mandatory, unavoidable part of the production and packaging process and nothing more.

When it comes to packaging, variable data is most easily defined as information that can only be added at the time of packing.

Our RF range of feeding systems – designed and built here in our UK factory – offer manufacturers a unique, flexible solution to code and/or label their packaging, in its flat form, where it can’t be done as part of the inline coding or labelling process.

The term COO (cost of ownership) is all-important in the world of coding, where the price of a machine isn’t a reflection on its overall lifetime cost.

Date coding your product online may be favourable but it’s not always the best way to ensure clear, accurate, reliable results. Here we explain why coding your sleeves offline may prove a better option.

Registered in England No. 03332329 VAT Reg. No. GB 690 3876 03

© Copyright 2025 Rotech | Website by Union 10 Design