When it comes to packaging, variable data is most easily defined as information that can only be added at the time of packing.

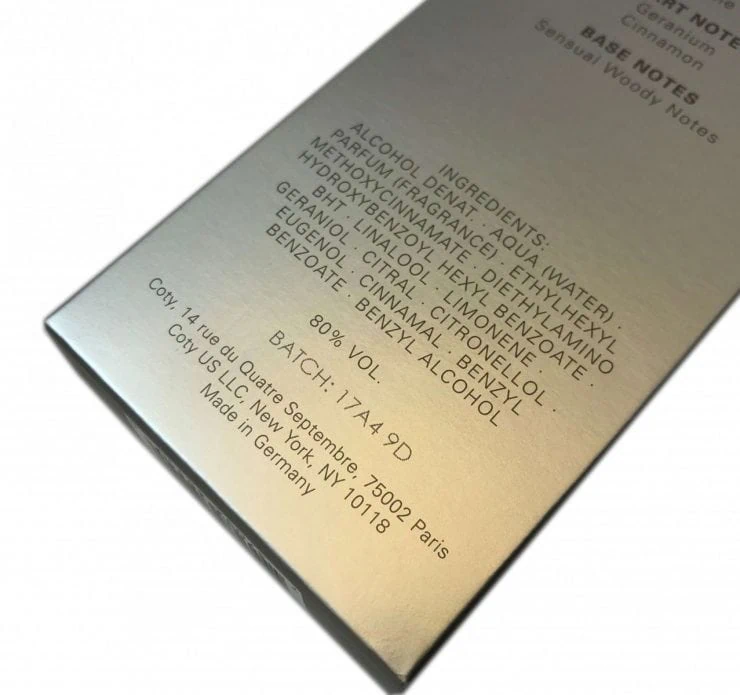

The most obvious example of this would be a use by/best before date that is applied to a food product or, within the pharmaceutical industry, a lot code or batch number and expiry date. In this latter example, the expiry date is for the patient’s reference to ensure the product is still within it’s designated life and therefore safe to use, but the lot or batch code is really there to protect the manufacturer, so that any product recall can be safely and effectively managed.

Such recalls or quality control measures could apply to just about any product in any sector, and it is common for a simple code to appear – often a Julian date code with a year designator such as 1251 to indicate the 251st day of 2021. Again, a variable that can only be added at the point of production or packing.

Beyond batch or date coding, variable information can be an entire description of the product. Many products have multiple variants or “SKUs” and holding packaging in stock for each of these is expensive, both in terms of the value of the stock and in terms of the warehousing needed to store it.

There is a cost involved in managing the stock and, absolutely no guarantee that the right amount of the right variant will be available when needed. A solution is to simply hold stock of the different generic pack sizes, but to have a blank panel onto which the variable data (in this case the whole product description) can be added on demand. If the product also has some form of batch or date code, this can be simply added at the same time as this information will be known at the time the print is made.

Fortunately, there are well established coding or printing technologies available to cater for all types of variable information – be they fitted directly to a production line or to an offline piece of equipment such as a stack-to-stack feeding system.

The small area inkjet technologies such as CIJ (Continuous Inkjet) and TIJ (Thermal Inkjet) can take care of the smaller print areas, though with TIJ this may include a product description or nutritional declaration, while Thermal Transfer technology can cater for both small and large areas of print, provided contact can be made with the surface.

Large area inkjet systems using piezo technology can print full product descriptions directly onto porous surfaces such as outer cases or boxes.

Increasingly now, the source of the information is some form of ERP (Enterprise Resource Planning) and the printer can usually be networked directly to this to remove any possibility of operator error.

In summary, variable information can be both a regulatory requirement but can also be a useful tool for increased production efficiency and customer response.

If you would like to discuss any requirements for printing variable data onto your product or packaging, contact our friendly experts today