Blog

From company updates to helpful hints and tips - Rotech's blog is a one stop shop for coding & marking and packaging information.

Introducing the Integra Vivid – HMI display for Rotech Printers

Adjusting print settings, monitoring ink levels and editing print jobs is now easier than ever, with the addition of the Integra Vivid

Trim Your Waste & Maximise Your Productivity – Go Lean With Your Coding and Marking

By going lean with their coding and marking, many manufacturers have boosted their productivity, welcomed cost-savings and even improved their sustainability credentials – a key factor for many consumers when making a purchase decision.

Coding and Marking – More Than Just a Necessity

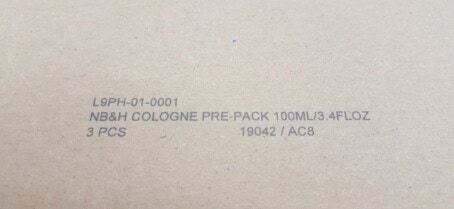

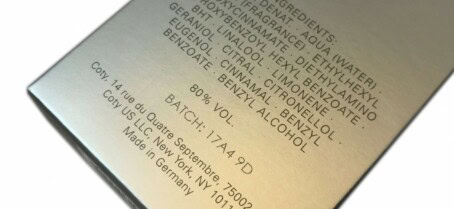

Coding and marking, the process in which variable data such as lot codes, batch numbers and barcodes are applied onto products, packaging or labels is often seen as a mandatory, unavoidable part of the production and packaging process and nothing more.

TIJ Printers Light the Way For Candle Producer

A candle manufacturer has boosted its ability to meet growing demand for its premium products by swapping messy and inflexible old coding systems for four clean and flexible, low-maintenance thermal inkjet (TIJ) printers from Rotech.

Manufacturers left in a Sticky Situation due to Label Shortages

When whispers of label shortages began during 2021- many thought that the problem would be resolved within a matter of months. However, like the labels, the problem has stuck, and lead times can span up to 3 months, causing problems for manufacturers across the globe.

RF Compliance Takes The Complexity Out Of Serialisation

With the ability to generate, print and verify serialised 2D codes on cartons, the RF Compliance offers an instant, reliable and easy-to-use solution for pharmaceutical manufacturers.

Variable Data Printing in Packaging

When it comes to packaging, variable data is most easily defined as information that can only be added at the time of packing.

https://rotechmachines.com/rotech-blog/12-things-to-consider-when-choosing-a-coding-marking-solution

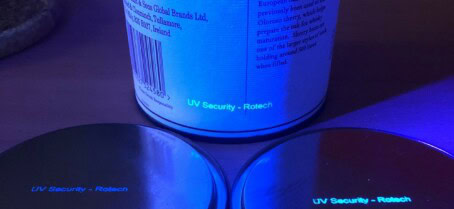

Rotech explains how brands can be protected with security features enabled by thermal inkjet.