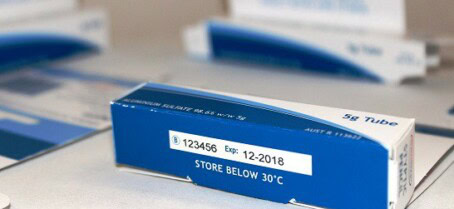

Why It’s Not Too Late to Get FMD Ready

Director of coding and marking specialist Rotech, outlines the impact the FMD is set to have across the pharmaceutical supply chain.

From company updates to helpful hints and tips - Rotech's blog is a one stop shop for coding & marking and packaging information.

Director of coding and marking specialist Rotech, outlines the impact the FMD is set to have across the pharmaceutical supply chain.

In the last decade, designers of TIJ (thermal inkjet) printers have been working tirelessly to address the technology’s limiting factors, and latest generation TIJ machines will outperform CIJ in terms of cost of ownership and print quality in most coding applications. But despite a discernible shift to TIJ on FMCG lines, outdated perceptions are still deterring many operations from moving to cartridge-based technology.

This year, Rotech Machines, the coding integration and feeding systems specialist, celebrates its 20th anniversary. To mark this milestone, company director Richard Pether looks back through the decades on coding technologies and what is instore for the future.

When buying a new offline coding system, choosing the shiny new printer is usually where the attention is focused, while working out how the pack will be fed to that coder becomes an afterthought.

Richard Pether, director at Rotech, explains why sometimes it simply makes sense to code offline, even for highly automated manufacturing and packing operations.

Offline coders are quietly handling the awkward jobs that would otherwise hold up production.

Registered in England No. 03332329 VAT Reg. No. GB 690 3876 03

© Copyright 2025 Rotech | Website by Union 10 Design