At its factory in Widnes, Cheshire, Paragon PE manufactures sanitisation products for the healthcare, personal care, sports apparel, household, veterinary and pet grooming sectors. These range from surface and hand sanitisers to clothing deodorisers, laundry detergents, odour eliminators and flea repellent sprays, sold under brands such as Paragon and Medipet as well as customers’ own labels. One of the company’s most successful products is Halo – a breakthrough low temperature detergent for which Paul was offered Dragon’s Den investment in 2010.

The last three years have seen exponential growth for the business; in this time the team of four has swelled to a workforce of 20, and by the end of 2016, there will be 30 people working at Paragon.

Paul Ward attributes this growth to the rise of the discount retailers – who represent a large chunk of Paragon’s customer base, but also to his company’s efforts to keep abreast of legislation.

Demand for many of our products is driven by regulatory requirements. Customers come to us because they can be assured that our products are compliant with biocidal legislation, explains Paul.

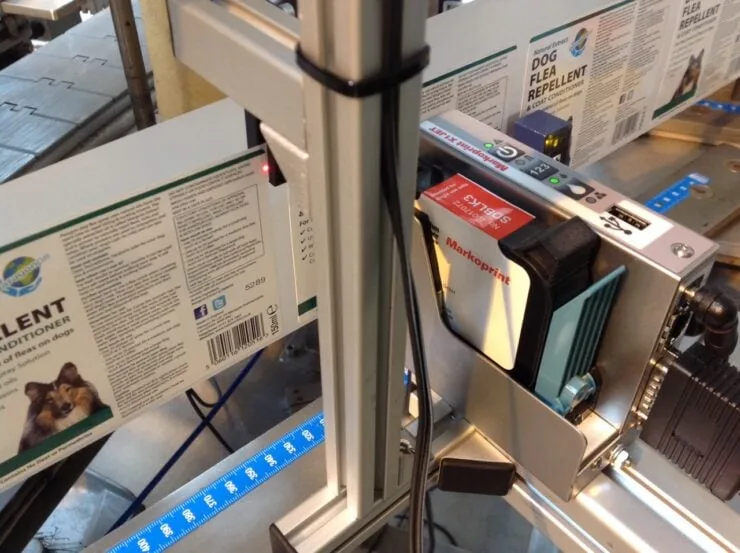

All of the company’s production is carried out on three filling lines, two of which are semi-automated, running at speeds of 22 bottles per minute and one which is fully automated, operating at speeds of up to 40 bottles per minute. Products are filled into plastic HDPE and PET bottles in a range of sizes, from 150ml right up to 5l, before being labelled and coded with Julian codes and expiry dates.

A thermal inkjet coder from Rotech has proved to be a flexible, reliable and economical alternative to continuous inkjet coding at Paragon PE, a fast-growing Cheshire manufacturer of sanitisation products. The versatile coder is being shared between two filling lines, applying codes directly to plastic bottles as well as via labels.

A thermal inkjet coder from Rotech has proved to be a flexible, reliable and economical alternative to continuous inkjet coding at Paragon PE, a fast-growing Cheshire manufacturer of sanitisation products. The versatile coder is being shared between two filling lines, applying codes directly to plastic bottles as well as via labels.