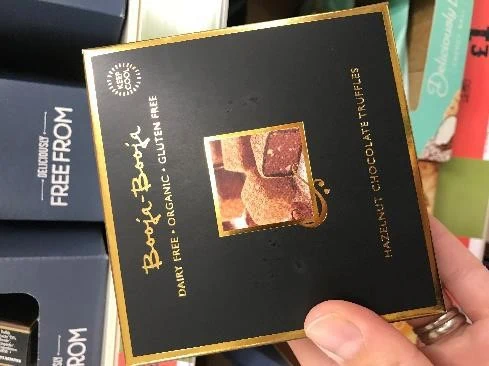

With ethical sourcing, sustainability and veganism rising gaining popularity with consumers in the UK and elsewhere, the company has continued to grow ever since. Taste remains the main driver behind the success of the company’s goods, with their truffles and dairy-free ice cream scooping two gold awards and a silver at this year’s FreeFrom Food Awards, as well as being Runner Up for the 2018 Overall Winner.

Today Booja-Booja employs over 50 people and supplies its branded products to a range of wholesalers and big retail customers, including Sainsbury, Waitrose, Holland & Barratt and Amazon. The company also exports to Australia and Germany.

Booja-Booja’s packaging reflects the high quality of its products, but the old coding process for truffles involved sticking data labels to the outer sleeves using a label gun, which was extremely time consuming and sometimes resulted in less-than-perfect positioning.

For traceability, we need to have the best before dates on our truffles but doing it manually was inefficient from both a time and cost perspective. Also, having an old-fashioned sticker on the pack didn’t really chime with our beautiful packaging says Tim.

With truffle production sometimes reaching over 1000 cases per day, these labelling issues were only getting worse as the company continued to expand.

Booja-Booja is growing every year, and we’re constantly looking for way to make improvements to our production line. Bringing in the RF Lite system makes our coding operation leaner and there’s also a welcome cost saving, he adds.

Realising that Booja-Booja might be better off switching to an automated coding system, Tim called in Rotech for a demonstration and the rest, as they say, is history.

The RF Lite takes flat cardboard sleeves from a hopper, feeds them through an inkjet printer to be date coded. It then stacks them again ready for use. The RF Lite can handle a variety of sleeve shapes and sizes and only takes seconds to swap between sizes without special tools or training. This was an important factor for the company, because they currently use five different sleeve sizes. A typical run for Booja-Booja’s truffle sleeves is currently 700 or 800 at a time taking under one hour.

Some coders can have trouble with code positioning and quality when handling different sleeve thicknesses and materials. Thin, light sleeve materials in particular can be problematic for systems that use a ‘push’ or ‘shuttle feed’ mechanism. The design of the RF Lite overcomes this potential feeding issue; sleeves are stacked vertically in a hopper, where friction wheels separate them and feed them one by one to the inkjet printer. The RF Lite’s hopper can also be easily adjusted to different sleeve sizes.

Print quality is another important consideration, both for legibility to meet legal requirements and to guarantee a high-end appearance. The iJet can print at 600 dpi. TIJ technology offers the added convenience of using a sealed cartridge, so there’s no need to handle messy inks and solvents.

Tim says it took just one month from approaching Rotech to have the new system up and running. Rotech engineers help with the hardware installation and Booja-Booja downloaded the software.

We needed a little support from Rotech to figure out how to get it set up to do exactly what we wanted,” says Tim. “Now it’s running like clockwork and we have no hesitation recommending it to others.

Rotech’s RF Lite with iJet TIJ printer has transformed coding operations for Booja-Booja’s luxury free-from chocolate truffles. The user-friendly coder has freed up substantial man hours and supports the brand’s ongoing expansion.

Rotech’s RF Lite with iJet TIJ printer has transformed coding operations for Booja-Booja’s luxury free-from chocolate truffles. The user-friendly coder has freed up substantial man hours and supports the brand’s ongoing expansion.