Finding the right entry-level batch-coding solution

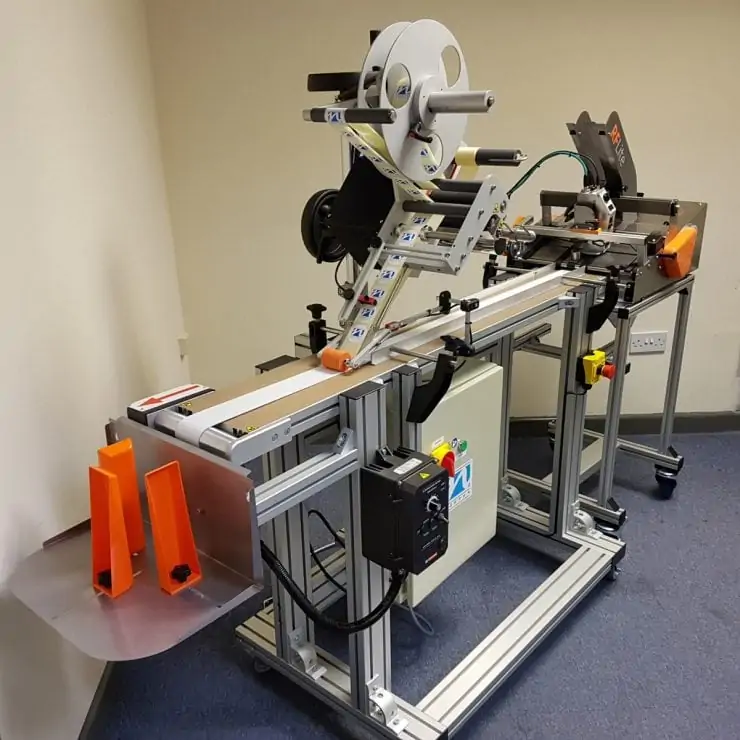

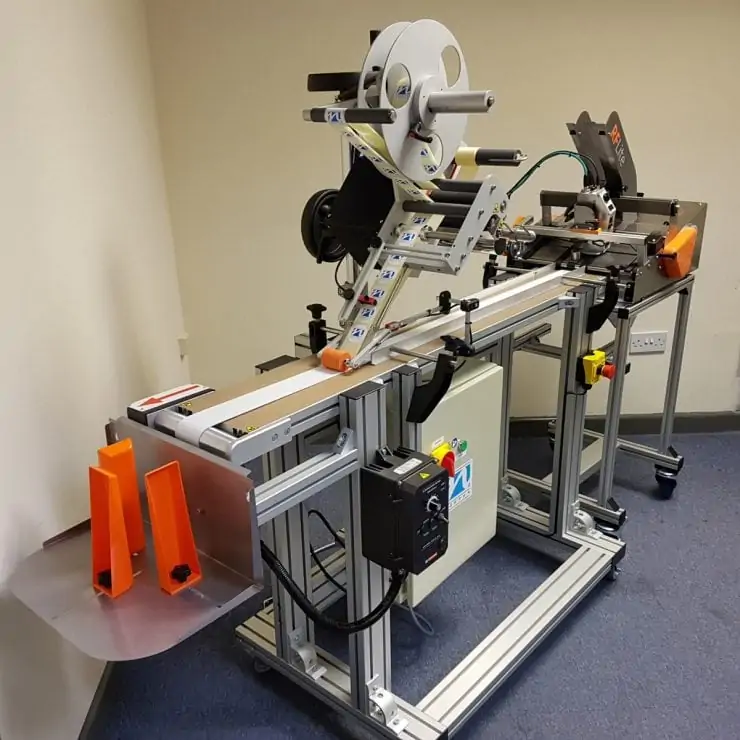

Initially, the company installed a Norpak labeller which automatically applied product labels to packaging. Knowing that the company were looking for a handheld printer to apply batch codes, Norpak referred the team to Rotech Machines. Sales manager and printing specialist, Steve Ryan, visited their facilities initially to demonstrate the handheld printer, however, it was soon clear that they needed a more flexible, future-proof solution.

When we made our first visit to demonstrate our handheld printer, we discovered that they actually had a variety of different packaging designs including small pocket pouches, small boxes, boxes with clear casing and shipping boxes. Using a handheld printer could lead to inconsistent printing and ultimately it would be more time-consuming.” said Steve. “Being new to coding, we helped them to see how they could very easily automate the entire process of applying codes, and integrate it with their labeller.

We returned to give them a demonstration of the RF Lite, an entry-level sleeve and carton feeder that is specifically designed for businesses looking to code their packaging for the first time. Small and flexible, it allows them to simply stack their cartons and pocket packs and automatically print batch and date codes directly onto their packaging using an integrated Integra One thermal inkjet printer.

For added flexibility we showed them how they could use the coding system independently or integrate it with their Norpak conveyor system, allowing them to code and label products.

The team were so impressed that they subsequently ordered two RF Lites so that they could use each method. In order to apply batch codes directly to their larger outer boxes, they ordered a further printer which was fitted to a slider rig, giving them even greater coding flexibility.

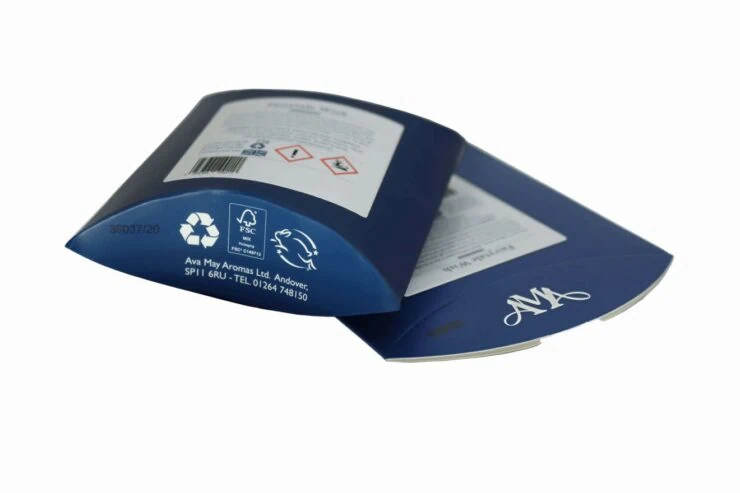

Applying coded labels to clear case packaging

Wax melts are one of Ava May Aroma’s most popular products. They sell 27 different varieties of scents in single pillow boxes or clear case multi-packs. To apply labels to the clear cases, the packaging is fed along their Norpak labelling conveyor, however, they needed to be able to apply a batch code to the label.

To achieve this, we mounted an Integra printer directly onto the labeller using a simple, fully adjustable frame; the batch code can then be printed directly to each label before it is applied to the product.

Clean, flexible, maintenance-free printing

When Ava May Aromas first approached Rotech, they were interested in acquiring a handheld thermal inkjet printer. The printers are small and lightweight, hence easy to hold and can apply codes and text onto a wide range of surfaces.

The Integra One is ideal for the RF Lite as it is so compact meaning that it can easily be integrated with any packing line. The maintenance-free printer produces high-quality prints which can be easily set up using the accompanying iDesign format creation software; users can create and edit batch codes, control output speeds, view job status, view print quality and check ink levels.

Ink replacement could not be easier. Each ink cartridge is simply clicked-in and clicked-out and can print up to 400,000 high quality prints, meaning low consumable costs.