In 2019 Rotech published an article highlighting packaging predictions for the upcoming year. Funnily enough, many ring true today. So, it’s not surprising that there is still a growing pressure to “create a circular economy by reducing single-use plastics” which is dictating the decisions of all manufacturers and consumers alike. But what steps are being made by Rotech to improve sustainability?

Rotech marking a path to improve Sustainable working

Picking, packing and paper packaging

The first, most obvious step to reduce waste for businesses is to target packaging. Rotech is no different and has removed unnecessary plastic when packing and shipping orders. With orders being sent out for both our main coding and marking range and Buy Rotech, the changes made will reduce waste and improve sustainability.

Plastic products used in abundance to protect items in transit, have now been replaced by 3 eco-friendly alternatives:

- Paper tape: A greener option to its plastic counterpart. Paper tape secures packages without compromising the recyclability of the outer case.

- Void fill paper: Rather than bubble-wrap, we now use void fill paper, which is not only environmentally friendly but also provides brilliant protection and an aesthetic finish.

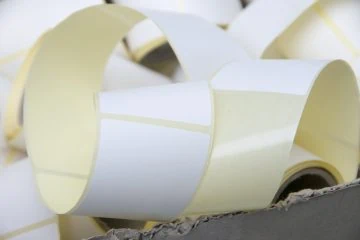

- Phenol-free labels: Phenol labels produce microplastics when they break down. Our new Phenol free Labels, use a vitamin C based coating which will reduce its impact on the environment

All replacements are 100% recyclable, compostable and natural. They work just as well (if not better) than the plastic alternatives, leaving no doubt that we made the correct decision.

Buying British

Rotech’s feeding and handling systems proudly wear the badge of “Made in Britain.” This in itself, is a benefit to the environment, because buying local generates a much smaller carbon footprint than shipping overseas. In addition to this, Rotech have complete control over the materials and processes used to manufacture the machines.

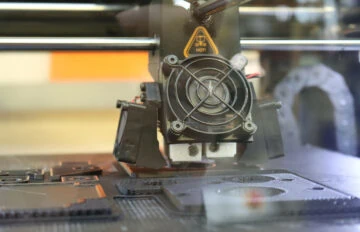

One example is the 3D printers used to create vital components for the feeders, an additive method of manufacturing where parts are made to order without waste. The printers increase efficiency, decrease stock holding and cut out the shipping process. The filament used is made from biodegradable plastic and renewable natural resources, yet another way to improve sustainability.

Helping customers to achieve cleaner, greener coding

Rotech’s team of experts offer support, advice and solutions to all industries wanting to improve the environmental impact of their manufacturing. Our customers might want to remove unnecessary steps from the production line, switch to a greener technology, or reduce consumables and servicing.

Our greener technologies include:

Large area printers that are an alternative to labels, allowing you to apply information and code directly to the box. When you remove labels, you also remove extra steps in your production process and ribbon or backing waste. Not forgetting there is no environmental impact caused by the manufacturing and delivering of label stock.

Thermal Inkjet is a greener technology when compared to CIJ coders and TTO printers. The maintenance-free systems, only require recyclable cartridge-based inks that do not contain harmful MEK fluids. Rotech can offer both on-line and off-line integration of TIJ printers to suit your specific application.

Moving Forward

With complete transparency, the journey to becoming eco-friendly is not over for Rotech; there is always room to learn, grow and adapt. The changes we have already implemented have had a small impact on the business but a significant impact on our carbon footprint. If you would like to keep up with our sustainability journey, why not sign up to our newsletter. We send monthly updates of industry and company updates and provide crucial coding and marking information.

Latest from Rotech

Receive your monthly issue of "On the Mark"

Keep your coding & marking on track with monthly updates from a team of industry experts!