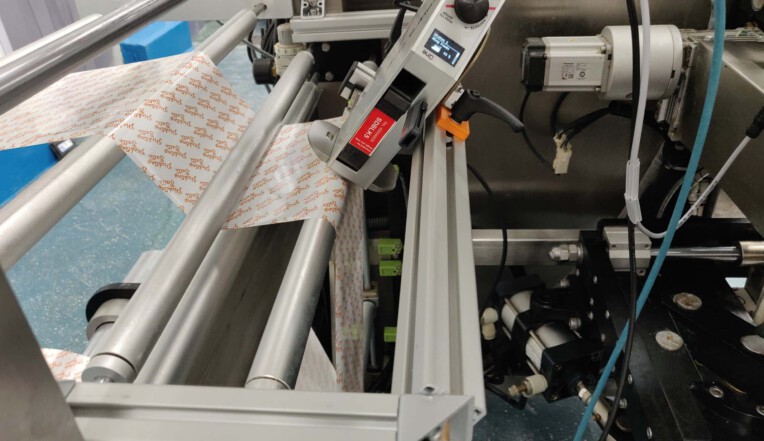

Flow wrapping, sometimes referred to as horizontal wrapping, is the process in which many popular household items, such as food products, electrical components and cosmetics are packaged.

The product is placed onto clear or printed polypropylene (PP) or polyethylene (PE) film where it is moved horizontally and sealed at both ends, providing a cost-effective, airtight and protective barrier.