Experiencing Long-Term Health Issues With Your CIJ Printer?

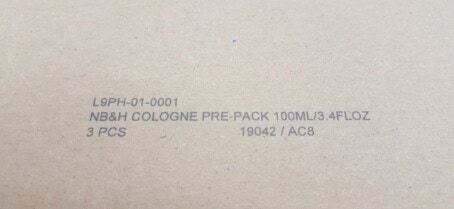

CIJ legacy printers are prone to long-term health issues and need regular maintenance check-ups. By taking out a Continuous inkjet (CIJ) printer and replacing it with a Thermal Inkjet (TIJ) printer, you eliminate chronic conditions, improving your overall line health immediately and indefinitely.