Product range & capabilities

Simply speaking, do the printers in their range meet your requirements? Information provided on the printer should include all the criteria you need to know, such as print quality, throughput, min/max print size and resistance to water and dust ingression (IP rating).

Also consider whether the printer can meet your future needs, not just the needs of the business now. If your predicting considerable growth, you should factor this in – can the solution grow with you?

Does the supplier offer a trial or demo of the printer? With many different models of printer and grades of ink available, it’s always beneficial to put the printer to test on your product or packaging prior to making that all important purchase decision. Like with any coding solution, a one-size-fits all approach doesn’t always work.

Expertise in the technology

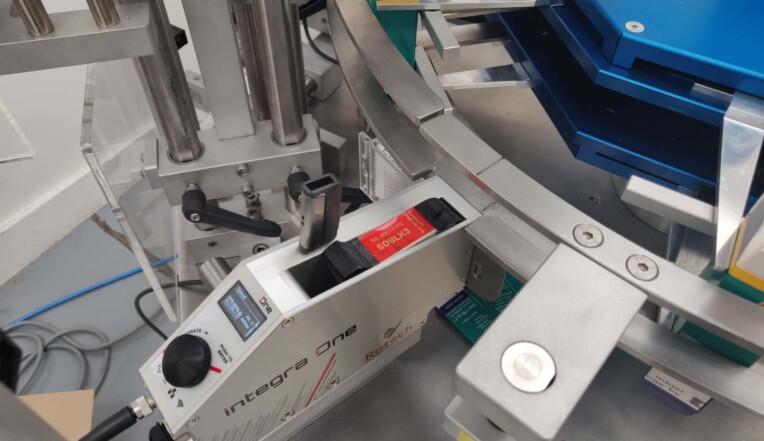

It’s inarguable that TIJ printers are relatively uncomplicated and are ideal for many coding applications and production lines. However, for the solution to be perfect and the installation to be efficient and seamless, knowledge around the printers and technology is crucial.

For an experienced engineer, integrating printers is quick and painless, with downtime kept at a minimum. They will also ensure that the positioning, parameters and settings of the printer(s) is ideal for the application in question.