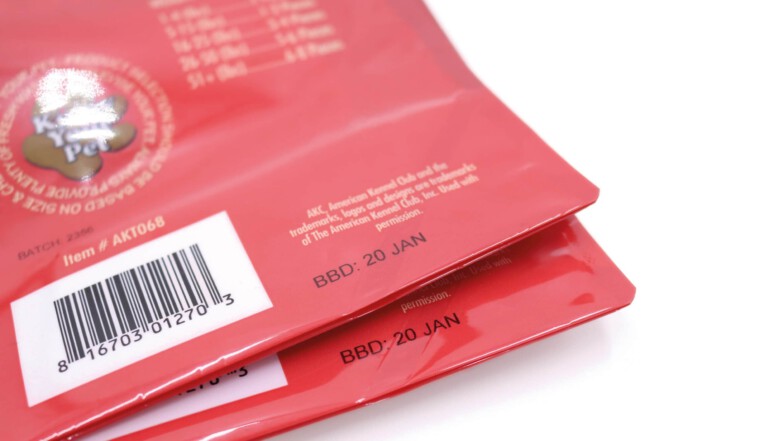

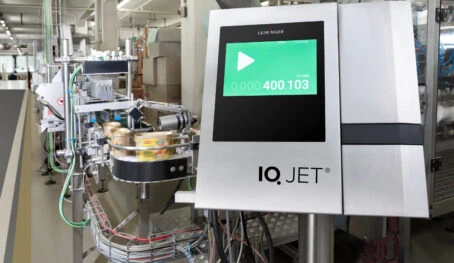

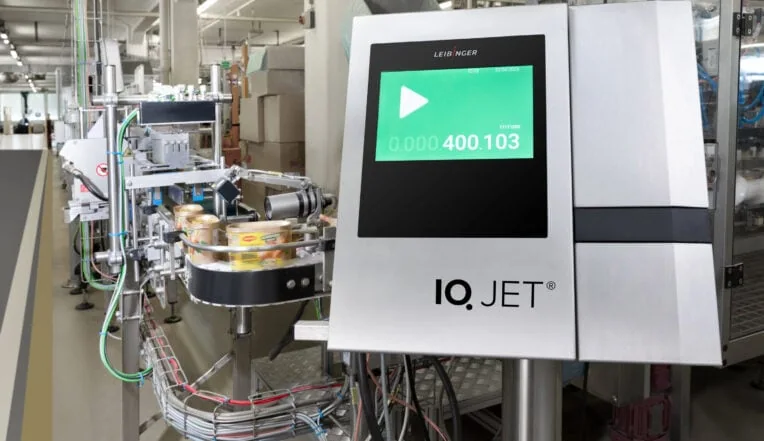

Accurate date codes are essential for safety, compliance and traceability. Whether it’s a use-by, best-before or production date, clear coding helps protect your customers and your brand. Reliable printing gives you full confidence in every product that leaves your facility.

Date code printing

Date coding solutions

Got a project to discuss?

Our coding experts are on hand help you find a solution to match your exact requirements.