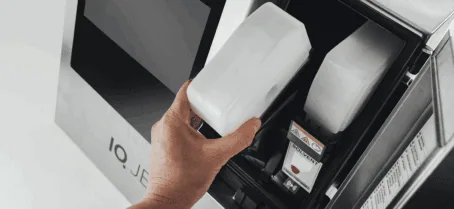

A feature completely unique to LEIBINGER CIJ, the automatic nozzle seal means that during downtime, the ink inside doesn’t dry up or clog. This eliminates cleaning routines and problems with print quality. Instead, you maintain maximum uptime and can code with confidence.

Achieve maximum efficiency with LEIBINGER's fully automatic nozzle seal technology.

It's CIJ, reimagined.

Below, we have outlined how the LEIBINGER nozzle seal technology addresses many of the challenges that have become all too familiar with traditional CIJ systems.

Conventional CIJ

LEIBINGER CIJ

Regular downtime and time spent cleaning

When production halts, ink in the printhead dries up and the need for cleaning occurs. This results in production delays, process inefficiencies and avoidable downtime, seriously affecting productivity.

Maximum uptime and productivity

LEIBINGER printers are ready to print when you are, even after extended production pauses. Because of the nozzle seal, they start up quickly and won't require labour-intensive cleaning. Instead, you can enjoy maximum uptime.

Inconsistent print quality

Fluctuating print quality is a known weakness of conventional CIJ, especially after a production pause. Spraying and irregular ink flow are common, and the mandatory cleaning cycle on restart can seriously affect ink viscosity. The result? Poor quality prints, product waste and a spike in operational costs.

Consistent, high-quality prints

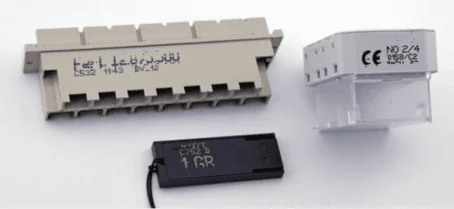

LEIBINGER’s fully automatic nozzle seal eliminates these issues. By keeping the nozzle airtight during downtime, it preserves ink viscosity and eliminates unnecessary cleaning so you're up and running within minutes, with consistent print quality from the first print to the last.

High daily operating costs

Conventional printers require time-consuming cleaning during restart, causing significant downtime. This can potentially halt production, resulting in costs as high as in the six-figure range. On top of that, frequent cleaning increases material usage, cleaning agent consumption and labour expenses. With an open ink circuit, solvent continues to evaporate even when the printer is idle, causing excessive ink and solvent consumption.

Lowest TCO on the market

The cost saving potential by switching to LEIBINGER CIJ is huge. With no need for manual cleaning, you save time, reduce the use of cleaning agents and lower labour costs. Downtime drops to a minimum. The automatic nozzle seal also minimises solvent evaporation by keeping the ink sealed off from air whenever the printer isn’t running.

Frequent solvent residues

Cleaning agents pose environmental hazards and potential health risks for your employees. On top of that, the accumulation of solvent residues in the production area is a serious concern, particularly in sensitive industries like food and beverage, where cleanliness and safety are paramount.

Safe for people, and the environment

Because start-up and shutdown require no cleaning cycles, your staff no longer need to regularly handle solvents. This promotes a safer workplace and keeps the production area clean and free of solvent residue. Eliminating the use of cleaning agents also helps reduce your environmental impact.

See what it could mean for your line

Want to know what a LEIBINGER CIJ could do for your line productivity? Let’s find out together. Whether you’re after a demo or just some advice, our experts are always on hand with practical insights and honest guidance.