Seeking a low-maintenance solution for ensuring seamless coding of their huge volumes of vegetable broth, MAGGI adopted the IQJET intelligent marking system. This innovative printer enhanced efficiency, minimised downtime and reduced operational costs, allowing employees to focus on quality and safety.

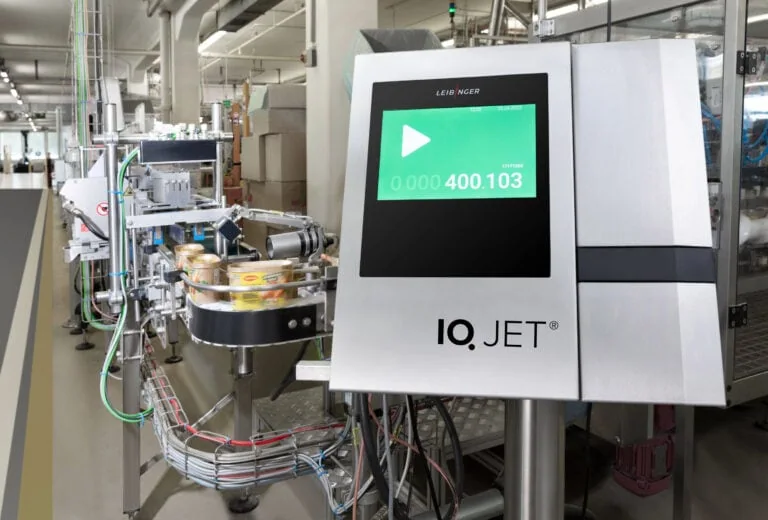

MAGGI boosts uptime with LEIBINGER’s smart, service-free IQJET

About MAGGI

A staple in kitchens worldwide, MAGGI is famous for its signature seasoning, soups, sauces and broths. It’s German subsidiary, MAGGI GmbH, operates under Nestlé Deutschland AG and has been setting the standard for quality food production since 1887. The Singen site in Baden-Württemberg is its largest German plant, employing nearly 550 people and producing over 40 million bottles of seasoning and 30 million cans of ravioli every year.

Committed to efficiency and innovation, MAGGI already had 50 LEIBINGER marking systems in place but was looking for an even smarter way to improve operations. That’s why they adopted LEIBINGER’s IQJET marking system, ensuring precision, reliability and seamless coding with minimal hassle.

The challenge: Keeping up with high-speed production

In MAGGI’s packaging division, precision is non-negotiable. With up to 120 employees working across multiple shifts, product safety, quality and efficiency are top priorities.

One major challenge? Coding 288g containers of vegetable broth, known as MAGGI “tainers”, at a rapid 70 units per minute. The best before dates and production details need to be clear and accurate, with no room for errors or downtime.

“The marking has to run flawlessly. Otherwise, there are real problems,” says Simon Keller, Technical Group leader in Packaging.

The solution: Intelligent marking with IQJET

To meet this challenge, MAGGI introduced IQJET – an intelligent marking system designed to work seamlessly with minimal employee involvement.

Ready to print when you are – IQJET automatically seals its nozzle airtight when idle, preventing ink from drying or clogging. When restarted, it’s ready to go – no cleaning needed.

Consistent, high-quality printing – By regulating ink temperature and viscosity in real time, IQJET ensures every code is clear and legible. The inks used are also completely food-safe.

Smart Integration – IQJET communicates directly with the packaging machine, identifying issues before they become costly problems. If something is off, the system alerts the operator and pauses production, preventing unnecessary waste.

The results: More uptime, less waste, and greater efficiency

Since adopting IQJET, MAGGI has seen tangible benefits:

Lower costs & improved sustainability – IQJET consumes just 36 watts on average and cuts solvent use by up to 50%, significantly reducing emissions.

Minimal maintenance, maximum productivity – IQJET is 5 year service free by design. This completely unique feature virtually eliminates downtime.

Employees focus on what matters – With fewer interventions required, staff can dedicate more time to quality and safety, rather than troubleshooting equipment.

“Any manufacturer who values efficiency and reliability will benefit from the IQJET. At MAGGI, we also appreciate how it allows our employees to focus on what truly matters, safety and product quality.” Keller concludes.

By embracing innovative, low-maintenance technology, MAGGI continues to set the benchmark for efficiency and quality, ensuring their much-loved products reach customers with the highest standards every time.

As LEIBINGER’s UK partner, Rotech can demonstrate the benefits of the IQJET on your production line. Get in touch to see how this game-changing solution can streamline your operations.

Got a project to discuss?

Our coding experts are on hand help you find a solution to match your exact requirements.