With over 190 years of coding & marking experience under our belts, we know how to match manufacturers to the optimum coding and marking solution for their application.

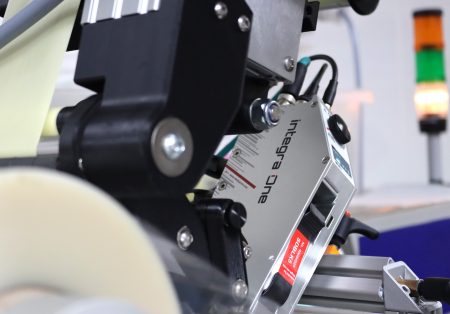

All of the above printing technologies have their own benefits and drawbacks, but at Rotech we advocate thermal inkjet (TIJ), as it is extremely versatile and usually the most cost-effective method for applying variable data to packaging.

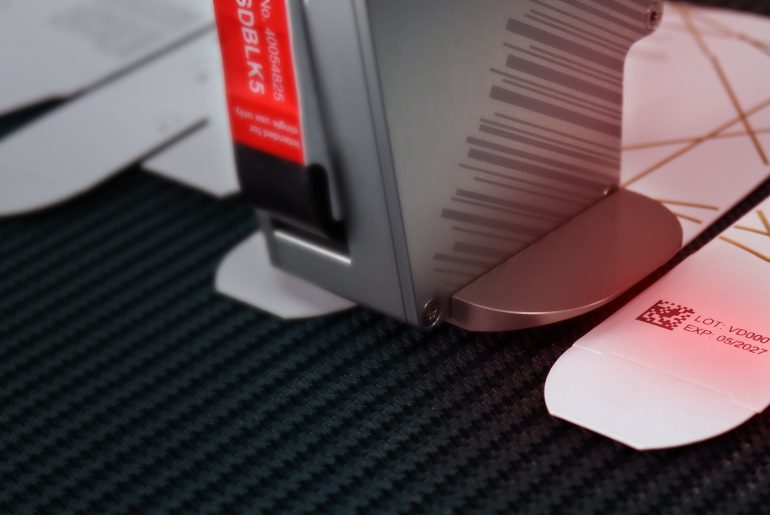

TIJ printers are completely maintenance-free, as every time you change the cartridge, you’re also changing the printhead itself. Each cartridge can also up to 600,000+ prints and only takes seconds to change, allowing you to print virtually 24/7 – minimalising downtime and maximising business profit.

We also provide a free samples & testing service whereby we find the most suitable and economical TIJ ink grade for your printers.