Rotech Machines will be exhibiting two exciting additions to its range at Empack 2017, highlighting how food SMEs can tackle cost, speed of coding and waste without compromising on packaging shelf appeal.

Leading UK coding and feeding specialist Rotech Machines will be exhibiting two exciting additions to its range at Empack 2017, highlighting how food SMEs can tackle cost, speed of coding and waste without compromising on packaging shelf appeal.

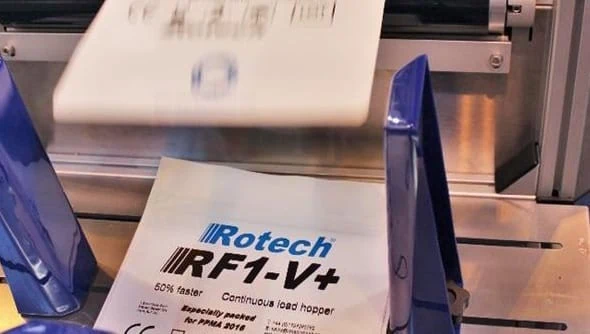

Headline products on show will include a new offline coder dedicated to pouches – the RF Pouch – Rotech’s newest pouch feedin g and coding system that can personalise codes at TWICE the speed of its predecessor, PLUS the compact, low-cost, RF Lite offline date marking system, ideal for artisan and SME food producers.

g and coding system that can personalise codes at TWICE the speed of its predecessor, PLUS the compact, low-cost, RF Lite offline date marking system, ideal for artisan and SME food producers.

With stand up pouches one of the fastest growing flexible packaging formats for food manufacturers, Rotech has answered calls for an offline coding machine that runs continuously without stopping or starting. By utilising vacuum pick and place technology and an innovative shingling infeed conveyor, the RF Pouch smoothly picks a pouch from a stack, places it onto a conveyor for printing, and transfers the printed pouch neatly onto another stack for collection. The result: reliable coding of pouches, including those featuring zippers and sliders, at speeds of 80 a minute.

The RF Pouch can print product descriptions, nutritional data, ingredient lists, multiple languages, as well as bar codes, date codes or batch codes, ensuring compliance with EU labelling regulations.

Faster pouch coding can be accomplished with the addition of a second shingling conveyor at the outfeed, while the larger capacity hopper can now hold up to 300 pouches, reducing the frequency of replenishing the system, resulting in even less machine downtime.

Leading UK coding and feeding specialist Rotech Machines will be exhibiting two exciting additions to its range at Empack 2017, highlighting how food SMEs can tackle cost, speed of coding and waste without compromising on packaging shelf appeal.

Headline products on show will include a new offline coder dedicated to pouches – the RF Pouch – Rotech’s newest pouch feeding and c oding system that can personalise codes at TWICE the speed of its predecessor, PLUS the compact, low-cost, RF Lite offline date marking system, ideal for artisan and SME food producers.

oding system that can personalise codes at TWICE the speed of its predecessor, PLUS the compact, low-cost, RF Lite offline date marking system, ideal for artisan and SME food producers.

With stand up pouches one of the fastest growing flexible packaging formats for food manufacturers, Rotech has answered calls for an offline coding machine that runs continuously without stopping or starting. By utilising vacuum pick and place technology and an innovative shingling infeed conveyor, the RF Pouch smoothly picks a pouch from a stack, places it onto a conveyor for printing, and transfers the printed pouch neatly onto another stack for collection. The result: reliable coding of pouches, including those featuring zippers and sliders, at speeds of 80 a minute.

The RF1 Pouch can print product descriptions, nutritional data, ingredient lists, multiple languages, as well as bar codes, date codes or batch codes, ensuring compliance with EU labelling regulations.

Faster pouch coding can be accomplished with the addition of a second shingling conveyor at the outfeed, while the larger capacity hopper can now hold up to 300 pouches, reducing the frequency of replenishing the system, resulting in even less machine downtime.